Description

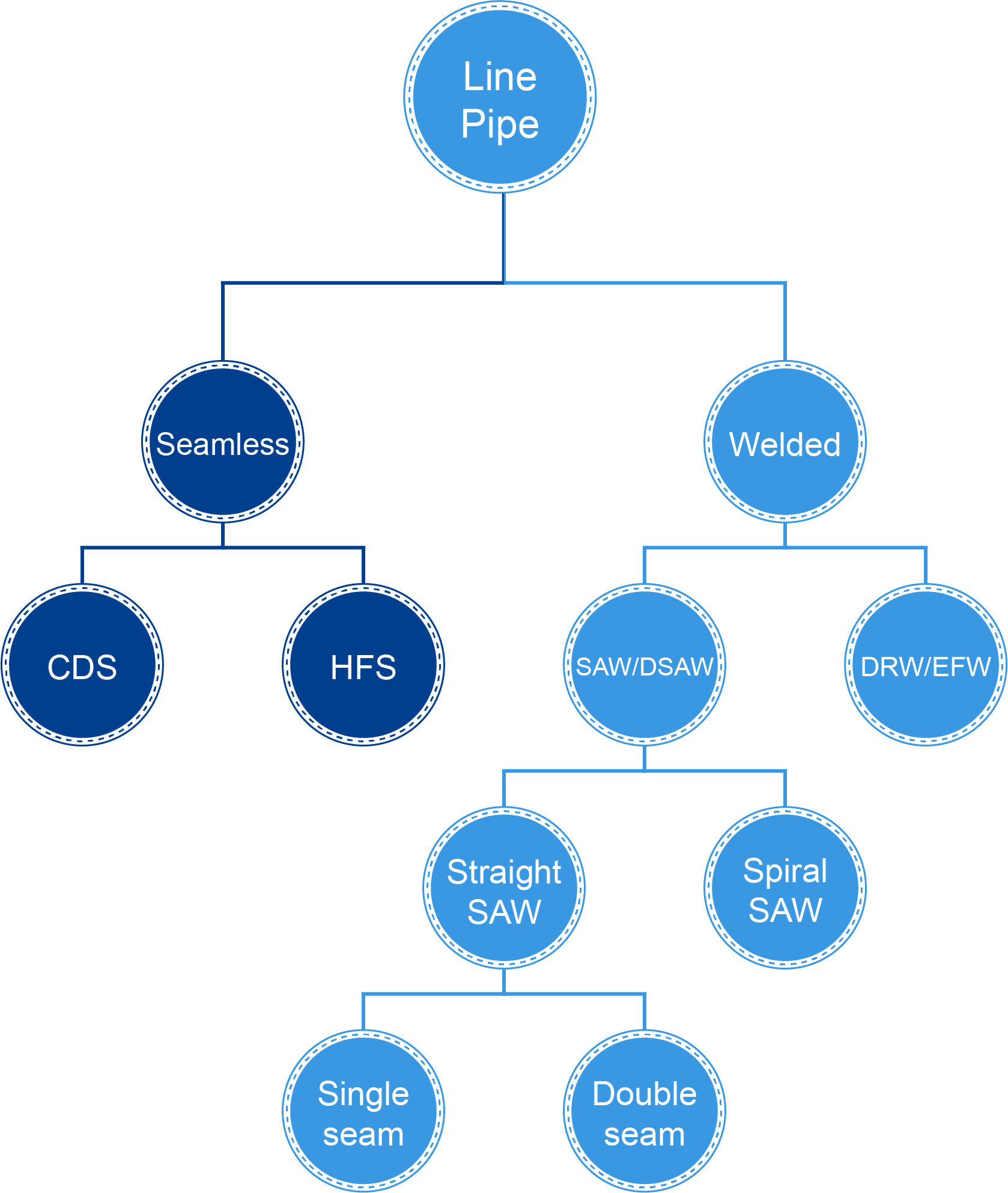

Seamless steel pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances that can flow — liquids and gases (fluids), slurries, powders and masses of small solids.

Seamless Pipe (and tubing) is made by extruding a steel block or by drilling a solid steel bar. Next, the extrusion or the drilled steel bar is cold drawn through a dye to achieve the diameter and thickness needed. Because this process can cause mechanical hardening, sometimes the material is annealed and straightened as a final process. Seamless Pipe & Tubing is subdivided as:

Cold Drawn Seamless, or CDS, exhibits precise tolerances and a good surface finish.

Hot Finished Seamless or HFS has less critical tolerances and a somewhat scaly finish and is not as strong as CDS.

For Drawn over Mandrel, or DOM tubing, the first stages of manufacturing are identical to the ones used to make electric resistance welded tubing, but in the finishing stages the entire flash weld is taken out and the tube is cold drawn over a mandrel. A mandrel is a round object against which material can be forged or shaped. The cold-drawn process provides the tube with better dimensional tolerances, improved surface finish and the strongest weld strength achievable.

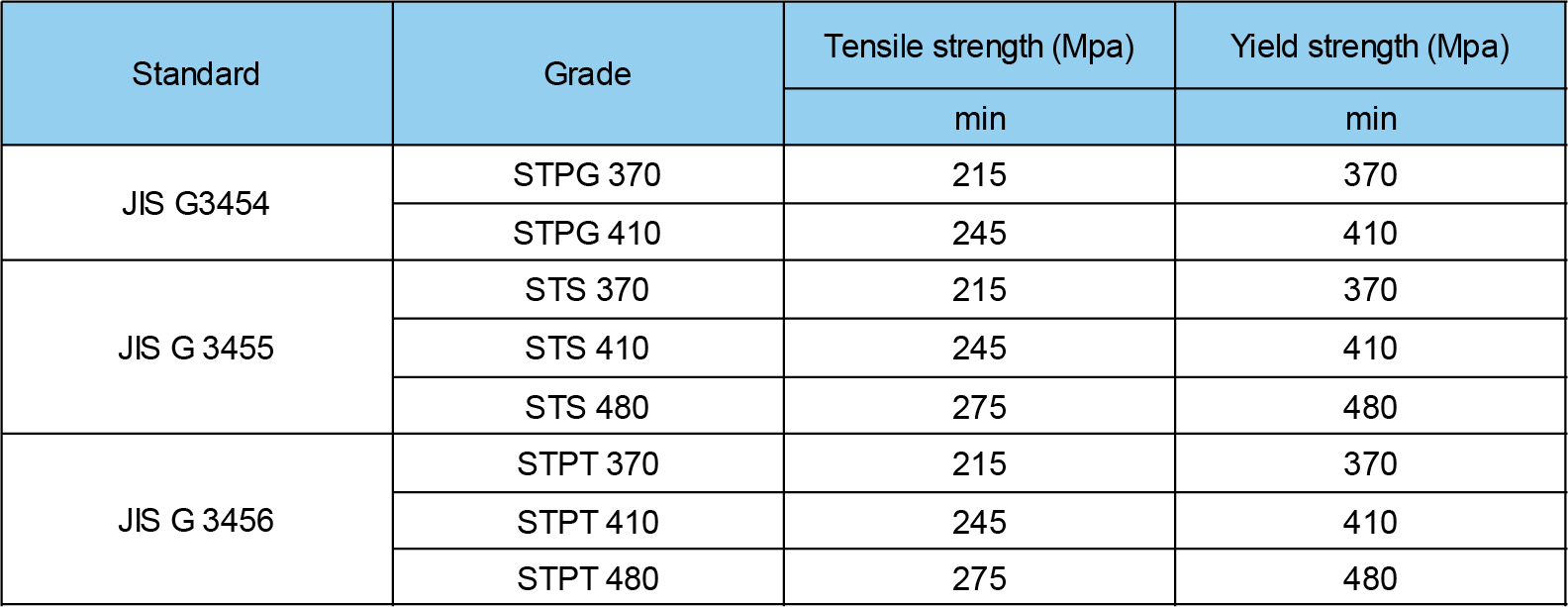

JIS G3454, JIS G3455, JIS G3456, and JIS G3461 are Japanese Industrial Standards for carbon steel pipes used for pressure service, high-pressure service, high-temperature service, and heat exchange service, respectively.

JIS G3454 covers the standard for carbon steel pipes used for pressure service at an ambient temperature range of -10 to 350 degrees Celsius.

JIS G3455 specifies the carbon steel pipes used for high-pressure service at an operating temperature range of -10 to 350 degrees Celsius.

JIS G3456 covers the carbon steel pipes used for high-temperature service at an operating temperature range of 350 to 650 degrees Celsius.

JIS G3461 specifies seamless carbon steel tubes used for heat exchange service, such as boilers, heat exchangers, and condensers.

JIS G3454, JIS G3455, JIS G3456, JIS G3461: Japanese Industrial Standard

Carbon steel pipes for high temperature service for conveying oil, gas and other fluid

Application: Oil, Gas and water delivery; Refinery, Boiler and Mechanical equipment manufacturer; structure construction; drilling, ship building and etc.

Grade and Chemical Composition ( % )

Mechanical Property

Rich production technology, advanced equipment, high automation degree and high production precision, complete molding. As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC, the company has won a number of national and provincial reputations.