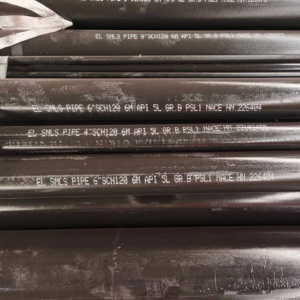

Description

Stainless steel is a versatile material comprised of a steel alloy and a small percentage of chromium — the addition of chromium adds to the material’s corrosion resistance, a trait that earned stainless steel its name. Because stainless steel is also low-maintenance, oxidation resistant, and doesn’t affect other metals it comes in contact with, it is frequently used in a large array of applications, especially in piping and tubing manufacturing.

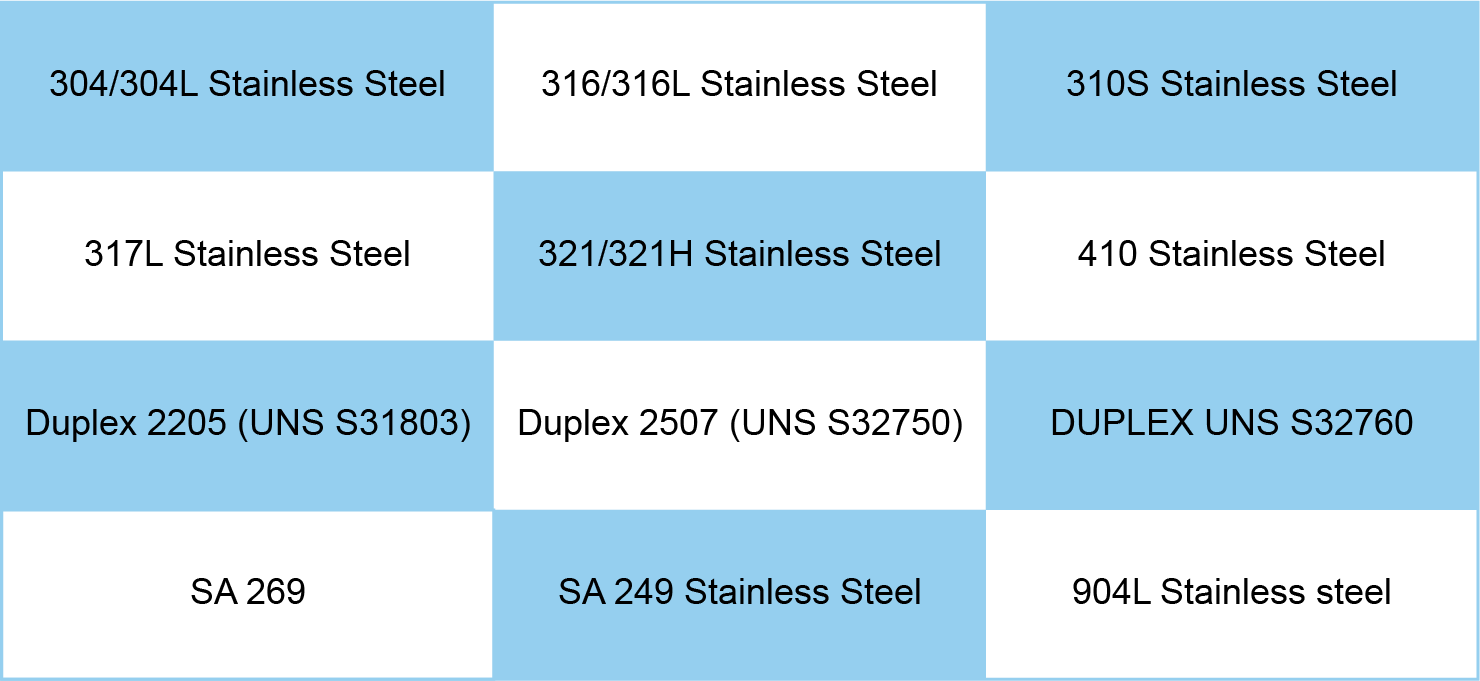

Material stainless steel grades

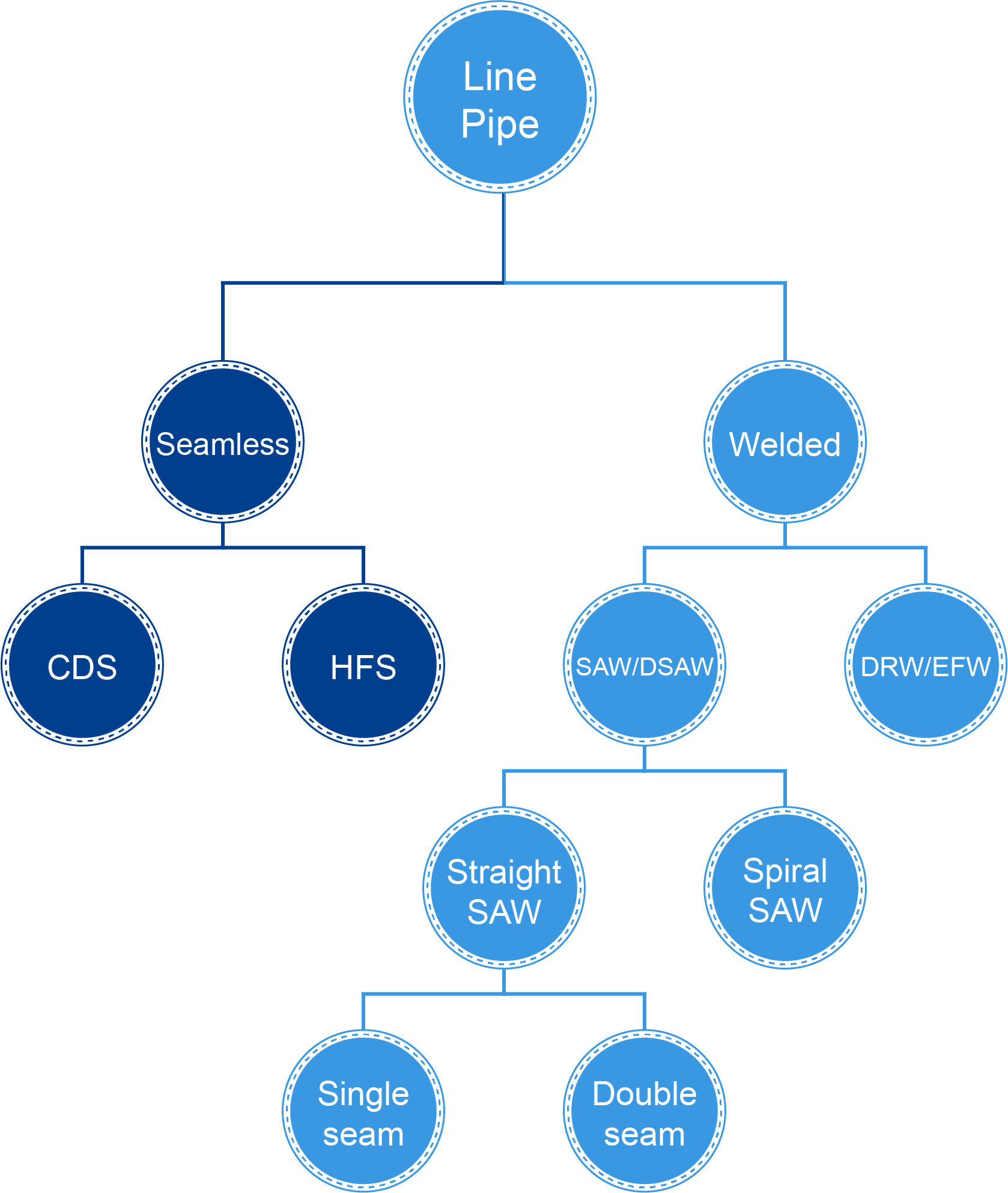

ASTM A789 & A790: American Society for Testing and Materials

Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

Application: Refineries; Nuclear Plant; Aerospace Industry; Chemical Fertilizer; Petrochemicals’ Oli & Gas and etc.

ASTM A789 covers duplex stainless steel (UNS S32205, S31803) tubing for general corrosion-resisting and low or high-temperature services.

ASTM A790 covers seamless and welded ferritic/austenitic stainless steel (UNS S31803, S32205, S32750, S32760) tubing for general corrosion-resisting and low or high-temperature services.

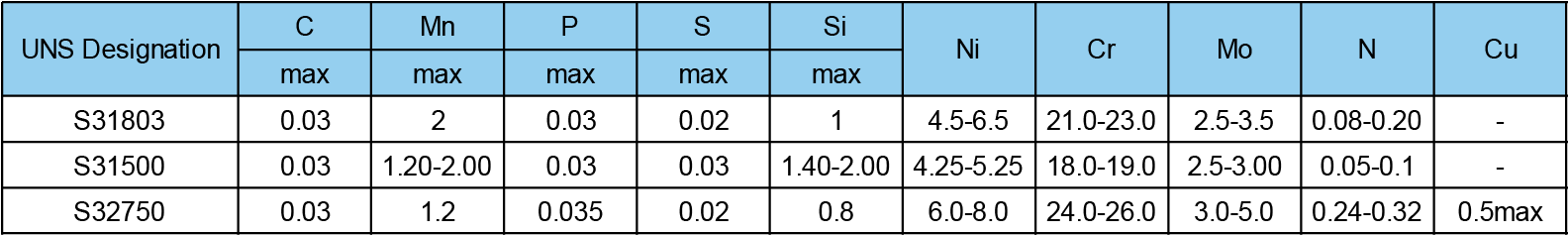

A789 Chemical Composition

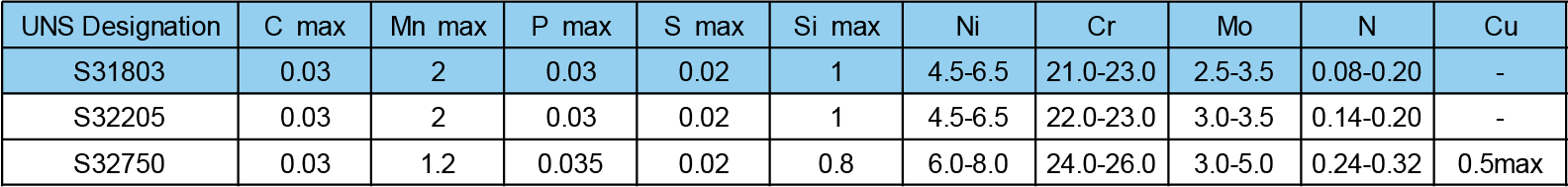

A790 Chemical Composition

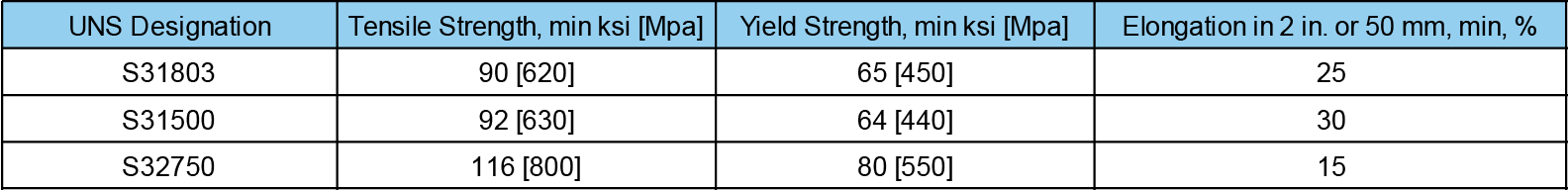

A789 Mechanical Properties

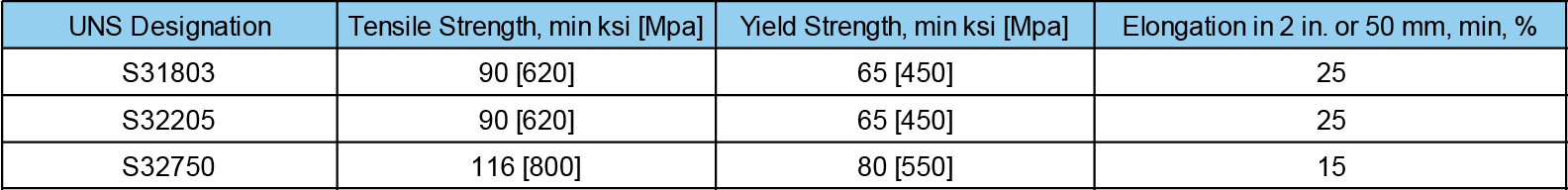

A790 Mechanical Properties

Rich production technology, advanced equipment, high automation degree and high production precision, complete molding. As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC, the company has won a number of national and provincial reputations.