Description

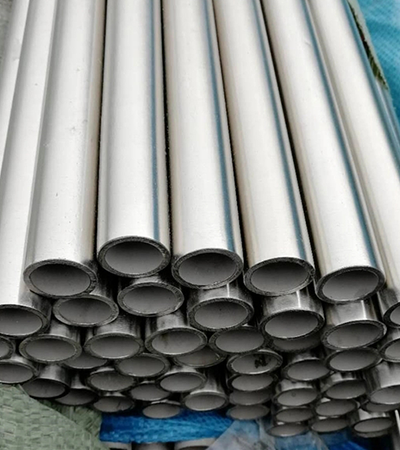

Stainless steel is a versatile material comprised of a steel alloy and a small percentage of chromium — the addition of chromium adds to the material’s corrosion resistance, a trait that earned stainless steel its name. Because stainless steel is also low-maintenance, oxidation resistant, and doesn’t affect other metals it comes in contact with, it is frequently used in a large array of applications, especially in piping and tubing manufacturing.

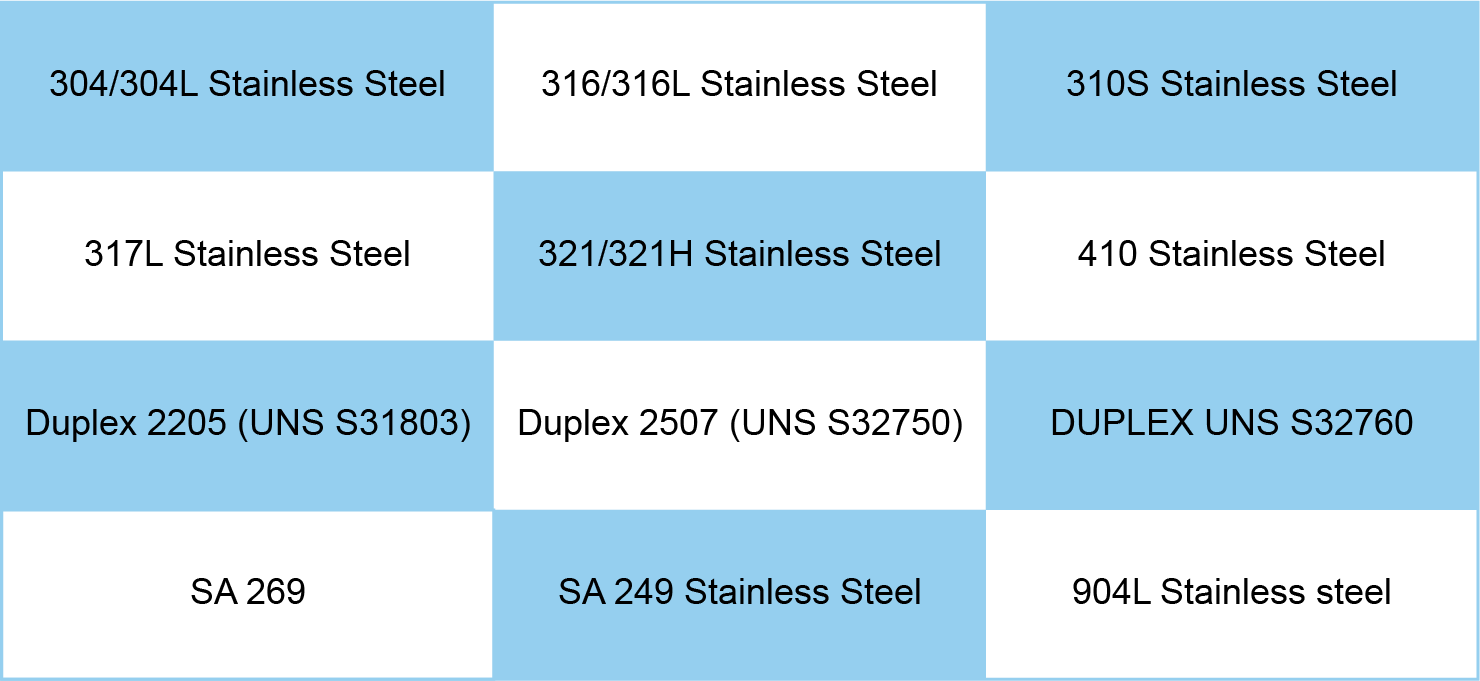

Material stainless steel grades

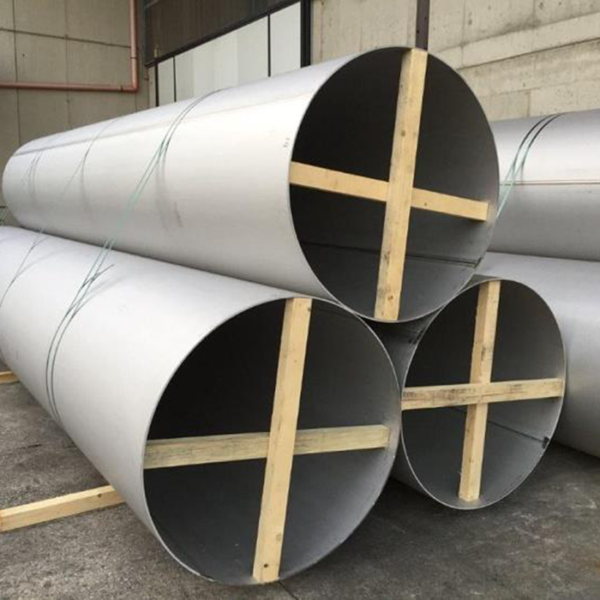

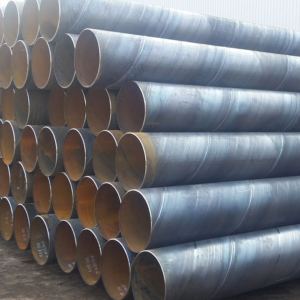

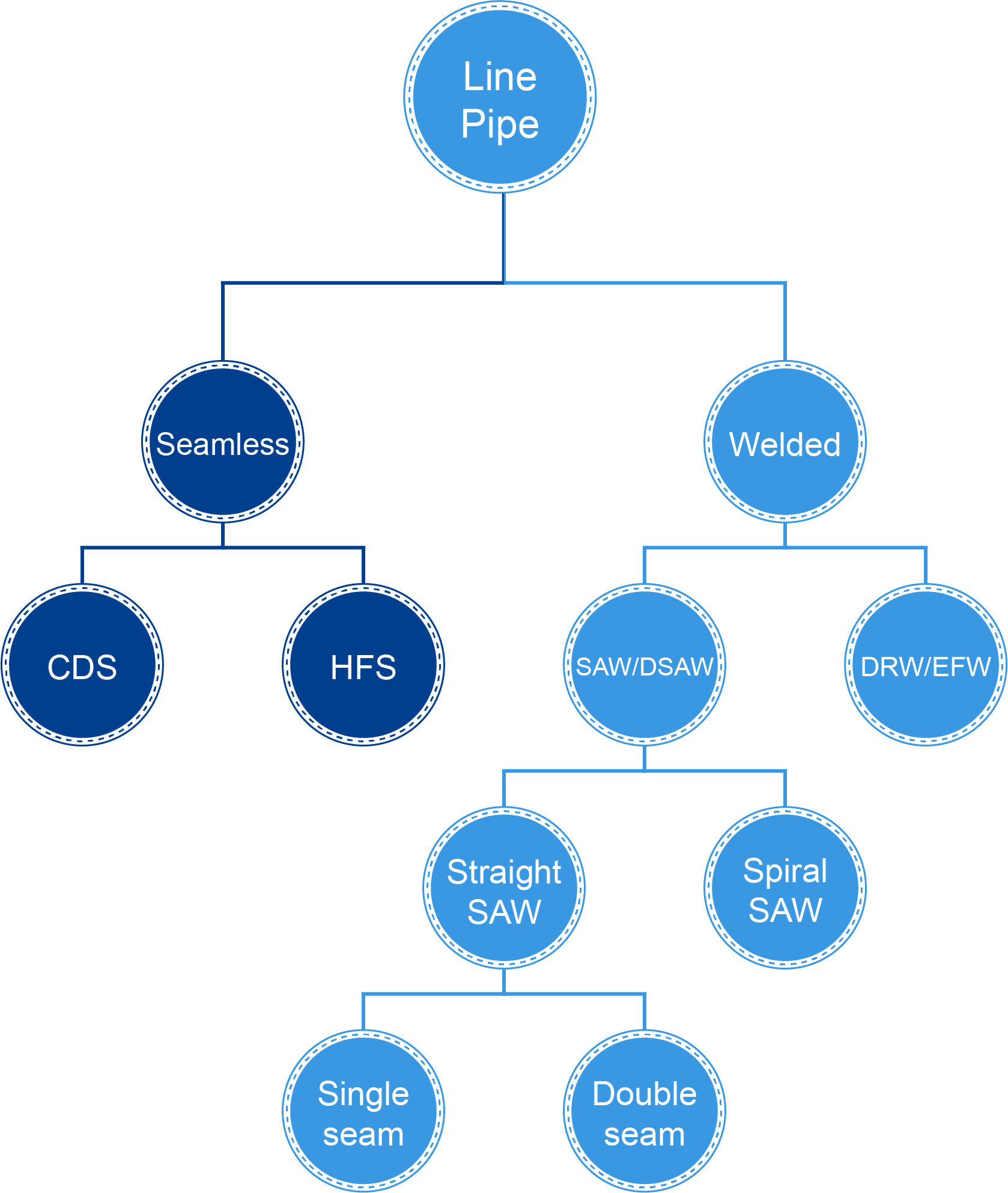

ASTM A358 is a standard specification for electric-fusion-welded austenitic chromium-nickel stainless steel pipe suitable for corrosive or high-temperature service. The pipes are made from various grades of austenitic stainless steel, including grades such as 304, 304L, 316, 316L, 317, 317L, 321, 347, and 904L. The pipes are produced in sizes ranging from NPS 8 to NPS 120 and are commonly used in applications such as chemical processing, food processing, and oil and gas industries. The pipes are produced using the electric fusion welding process, which involves the application of heat and pressure to join two pieces of metal. The finished pipes are then tested for quality and inspected for defects to ensure they meet the specified requirements.

ASTM A358: American Society for Testing and Materials

Electric-Fusion-Welded Austenitic Chromium-Nickel Stainless Steel Pipe For High-Temperature Service and General Applications

Application: Refineries; Nuclear Plant; Aerospace Industry; Chemical Fertilizer; Petrochemicals’ Oli & Gas and etc.

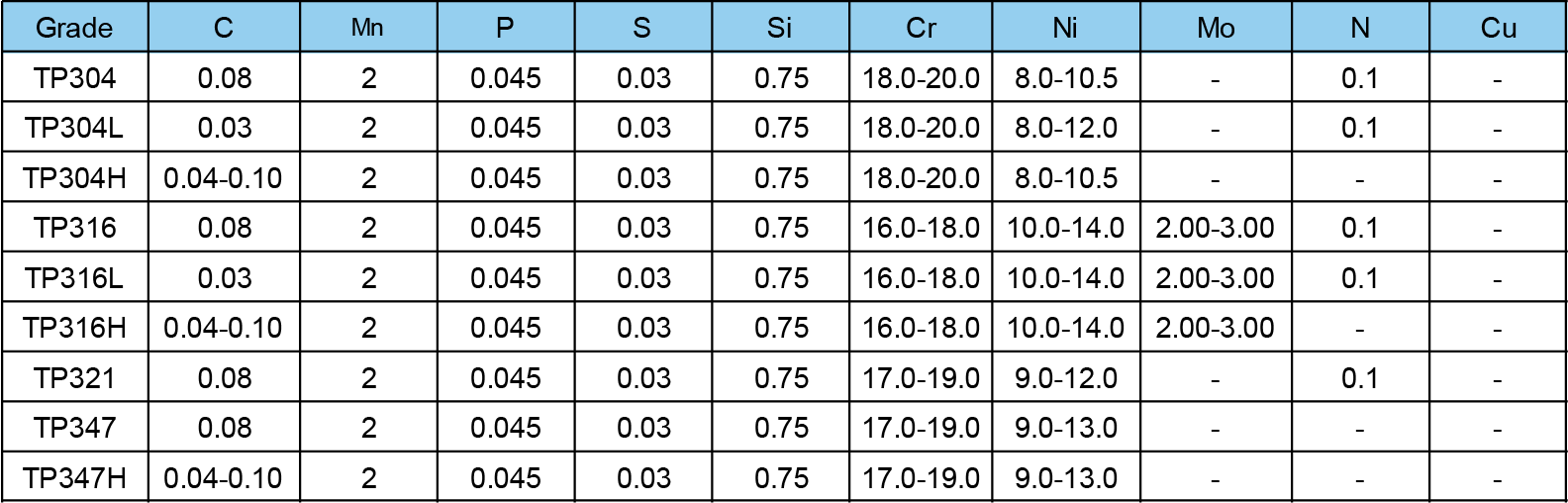

ASTM A358 Chemical Composition

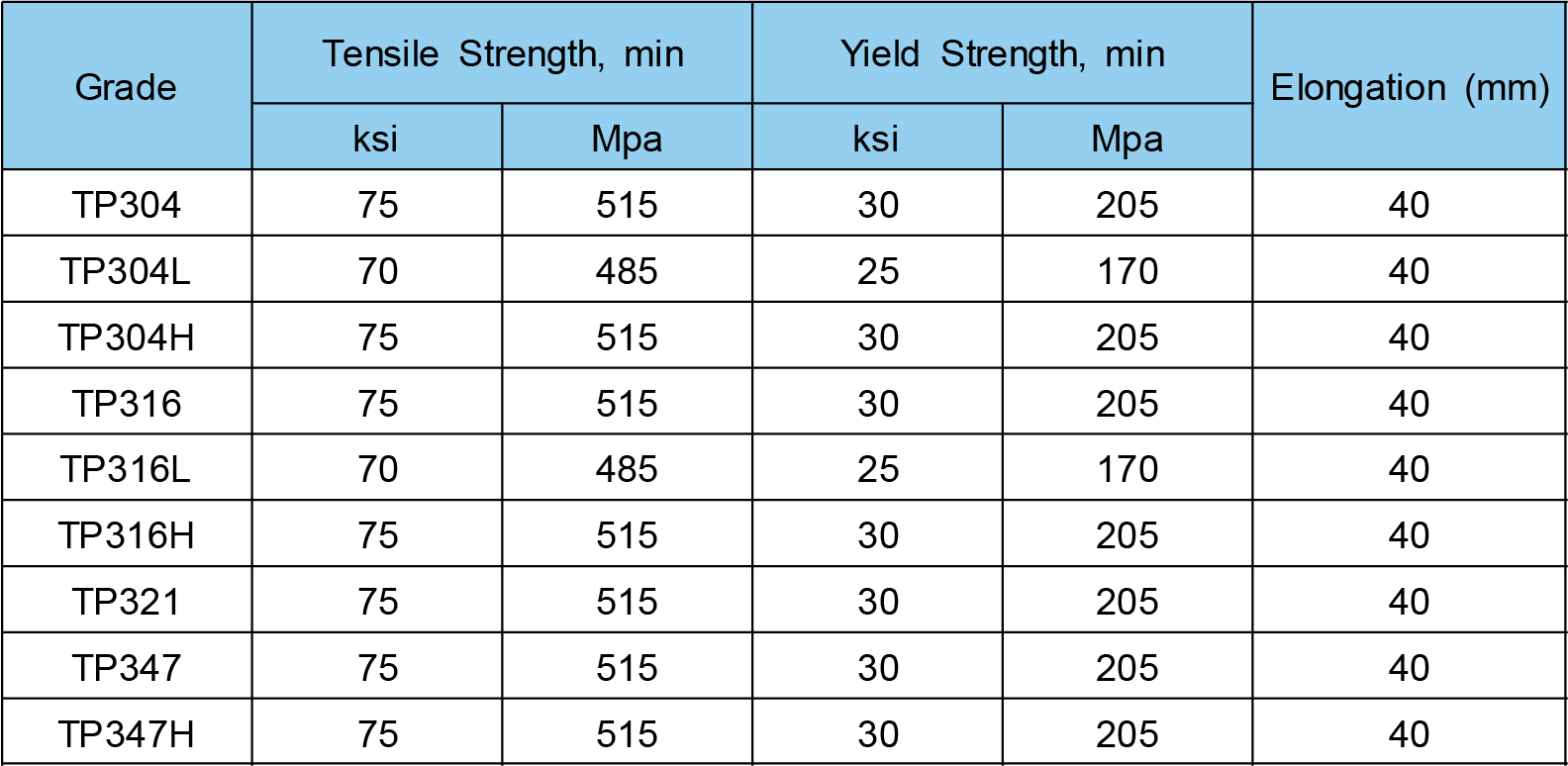

ASTM A358 Mechanical Property

Rich production technology, advanced equipment, high automation degree and high production precision, complete molding. As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC, the company has won a number of national and provincial reputations.