Description

Forged olets are fittings that are used in piping systems to provide an outlet from a larger pipe to a smaller one, or to a different pipe system altogether. They are similar to a combination of a flange and a fitting and are used in situations where a traditional tee or another fitting cannot be used due to space constraints or other limitations.

Forged olets are manufactured by a process called forging, which involves shaping and forming metal while it is hot using a hammer or press. This results in a stronger, more durable product than one that is simply cast or machined. Forged olets are commonly used in high-pressure and high-temperature applications, such as in the petrochemical and power generation industries. They are available in a variety of materials, including carbon steel, stainless steel, and alloy steel.

Weldolet fittings are used to create branch connections in lengths of pipe. They eliminate the need to place bulkier welded or threaded tees in line and they’re more flexible than tees, simply run your pipe and then weld fittings on.

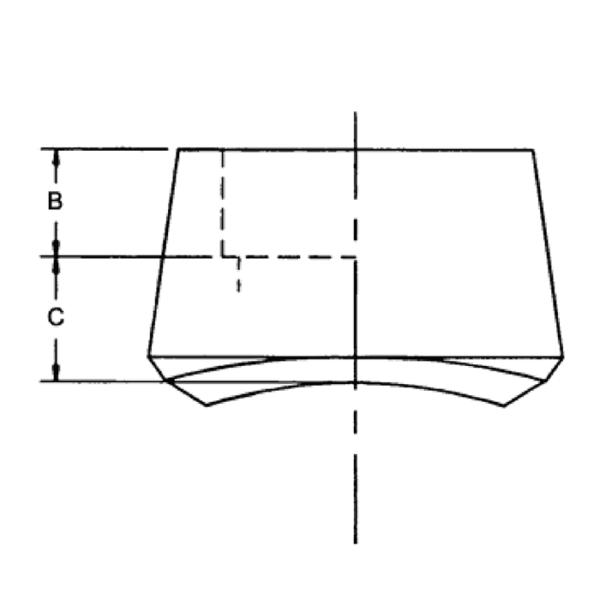

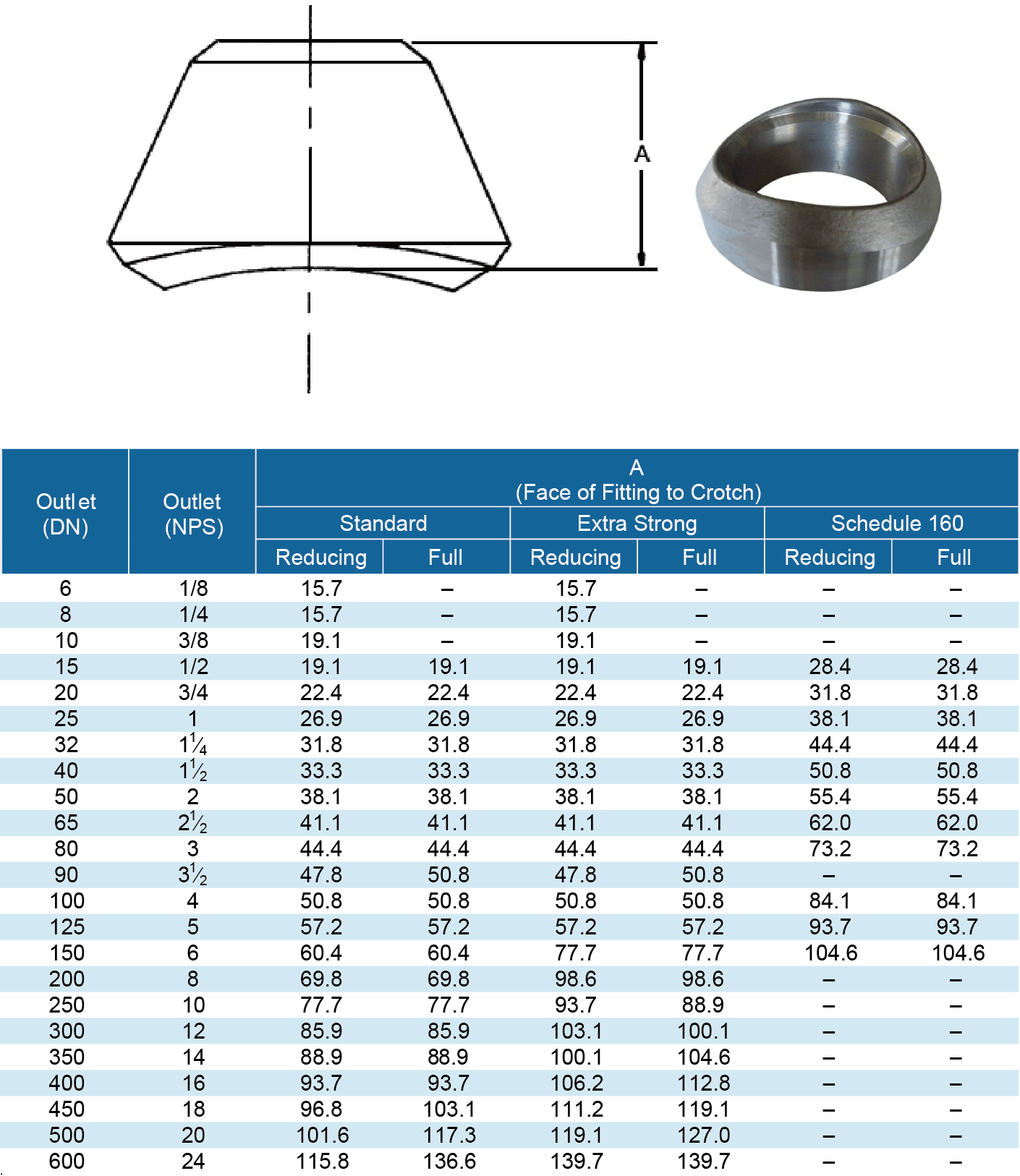

90°Branch Outlets—Buttwelding

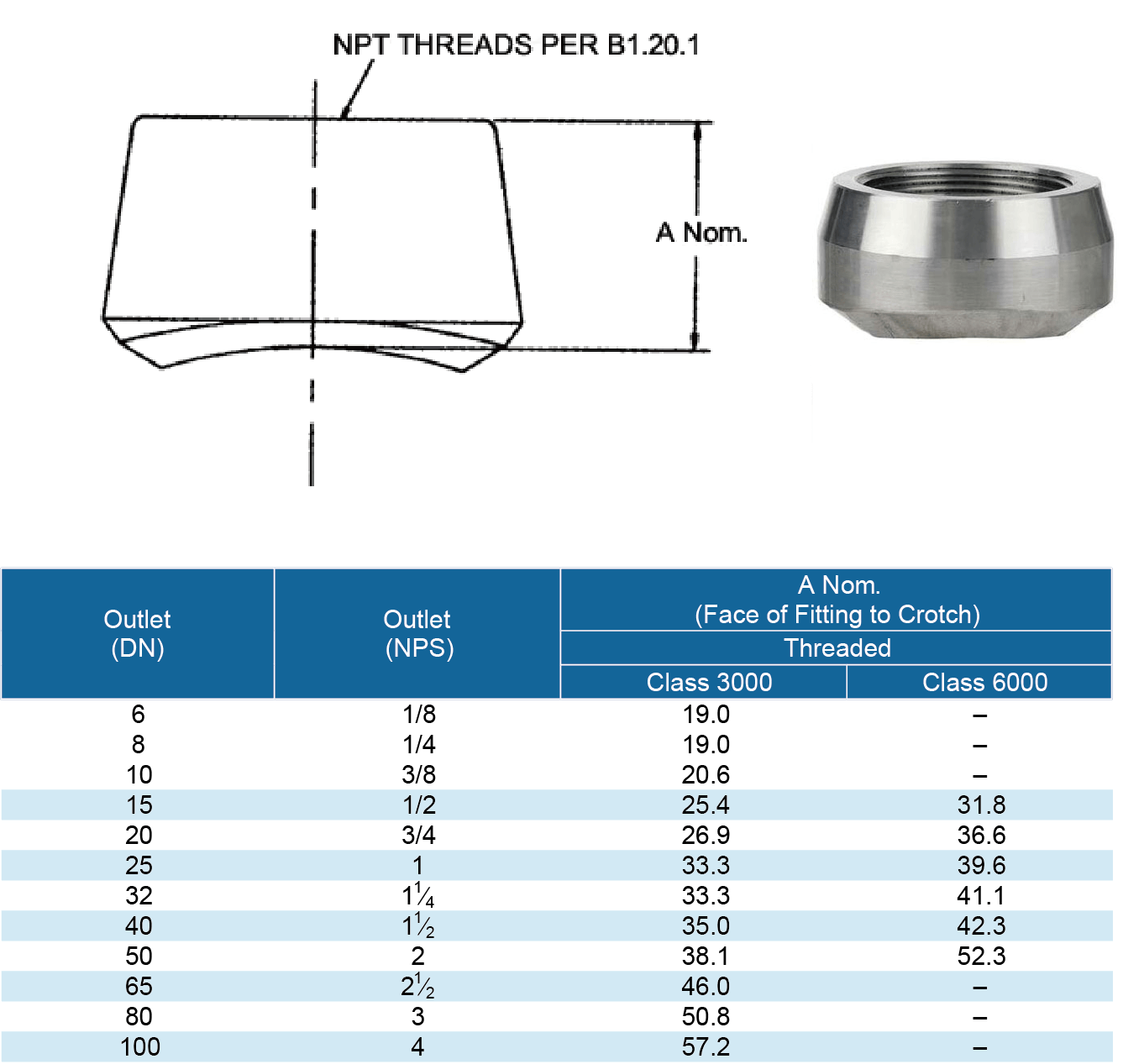

90°Branch Outlets—Threaded

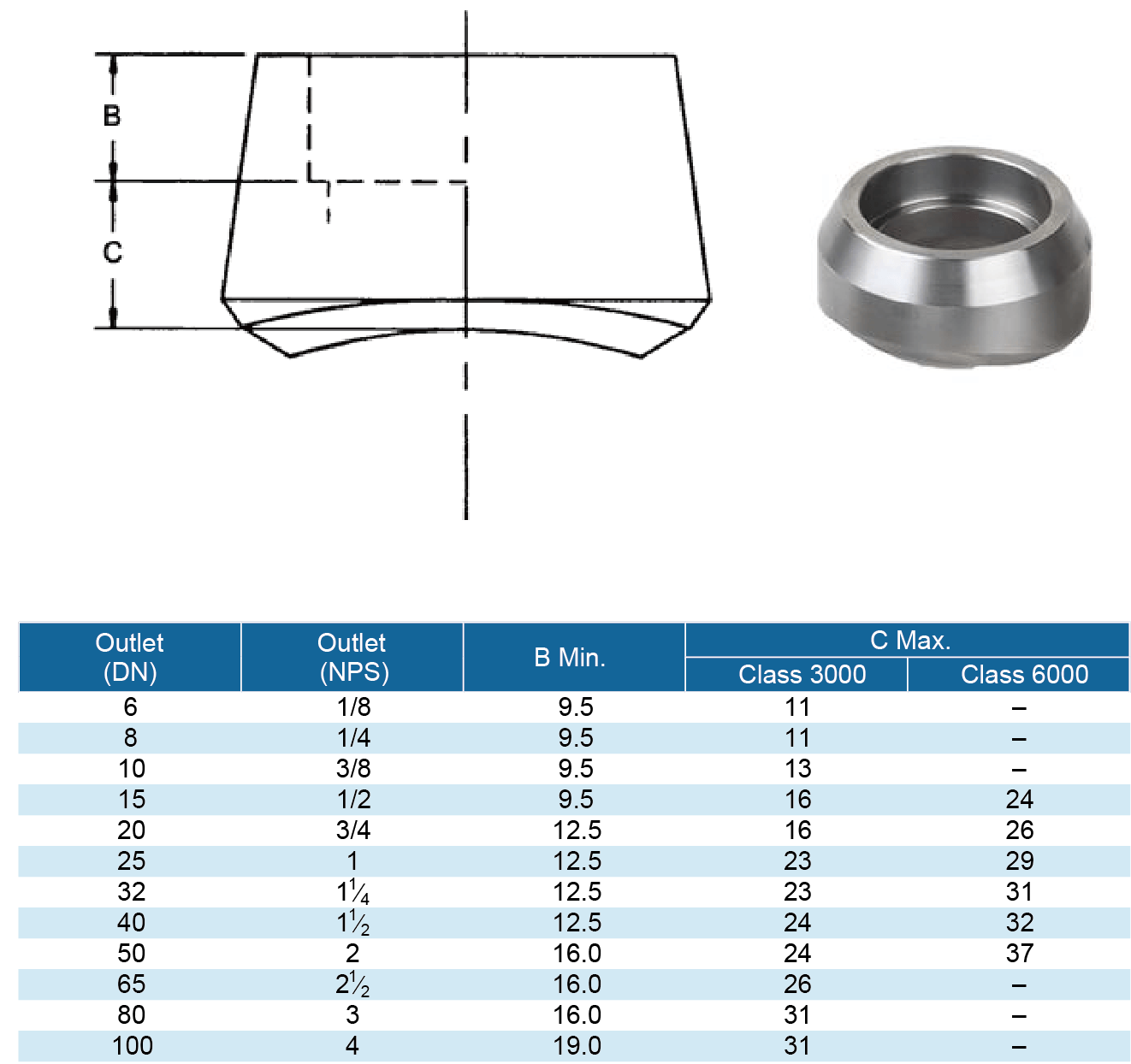

90°Branch Outlets—Socket Welding

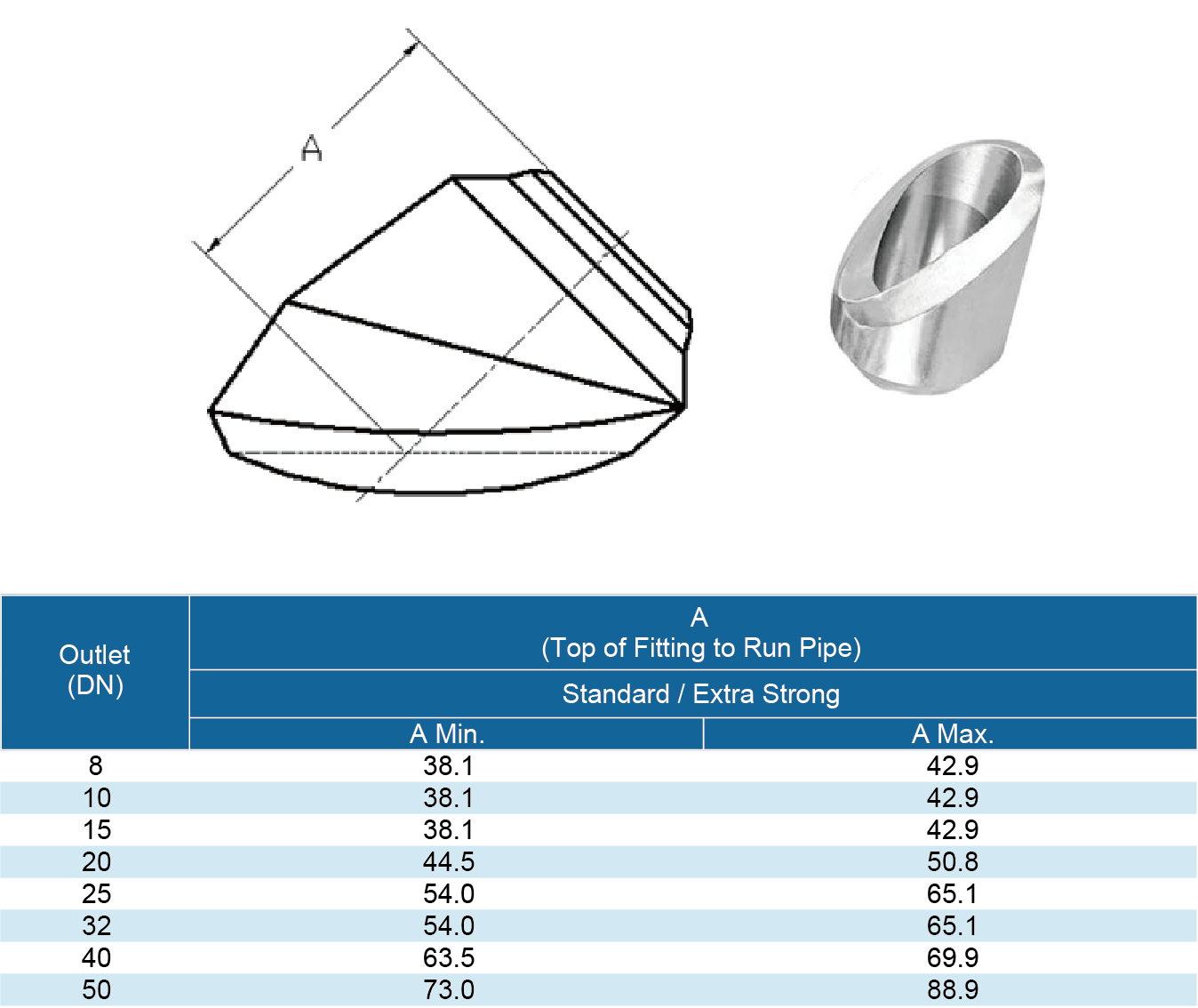

45°Branch Outlets—Butting

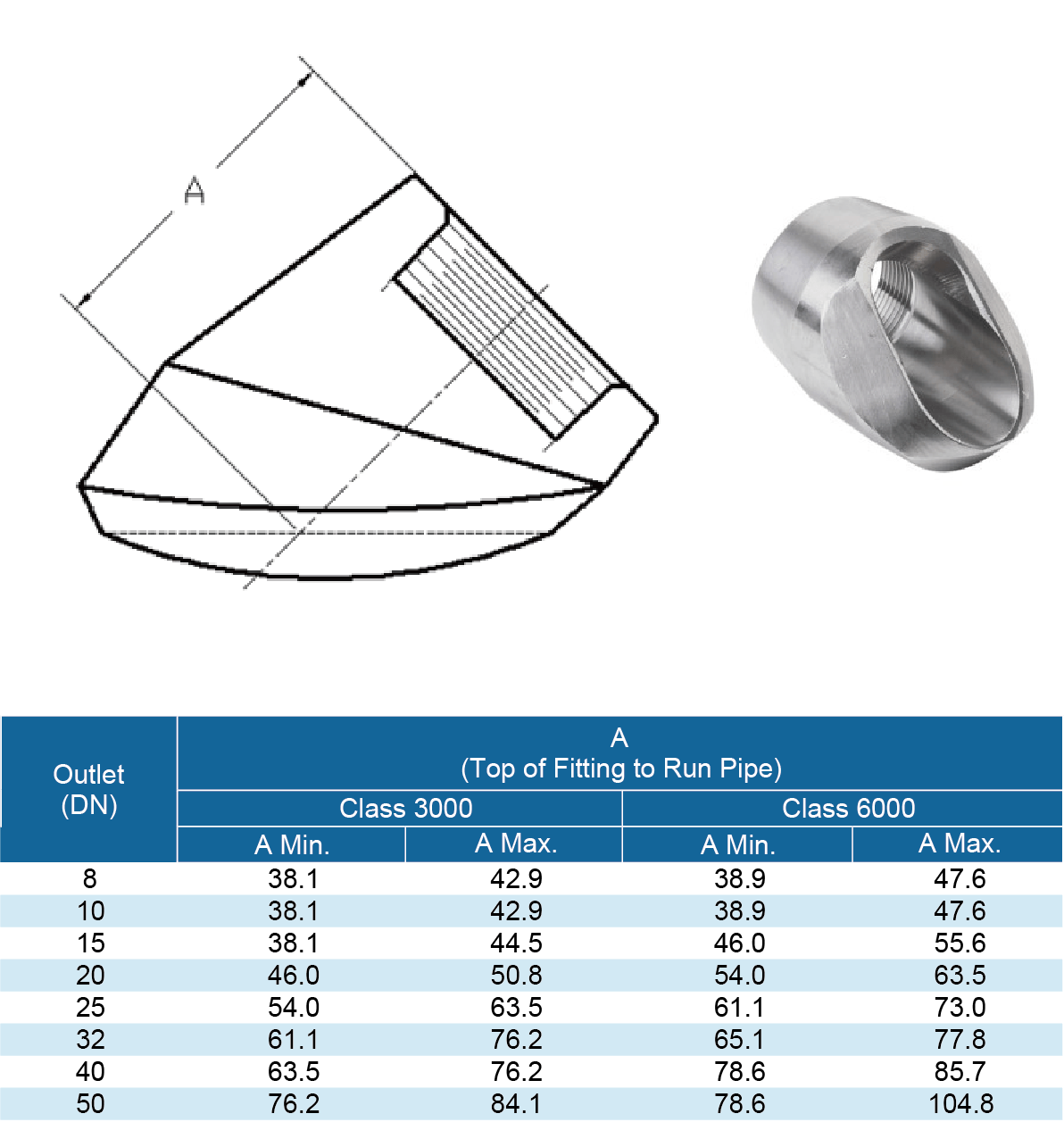

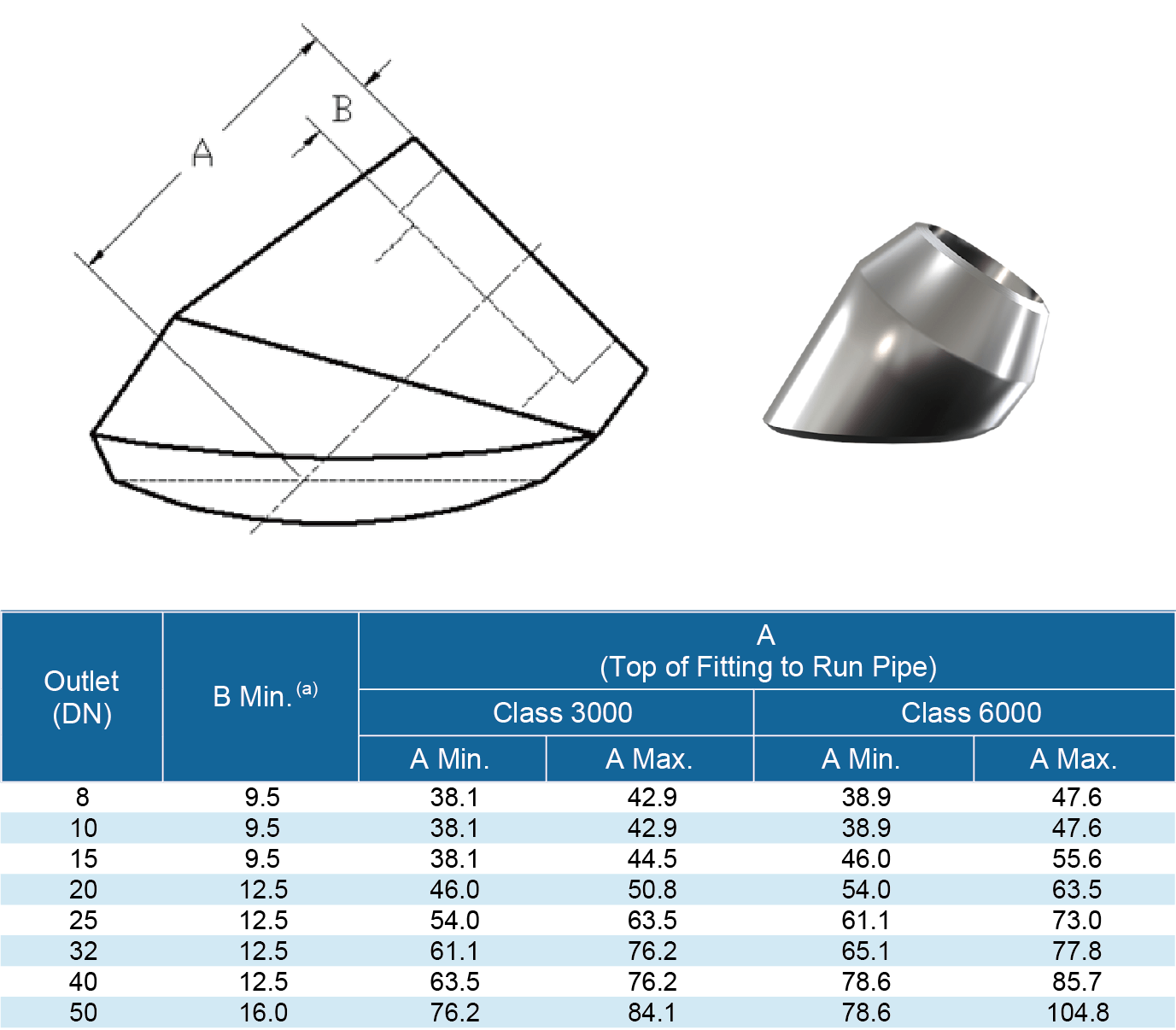

45°Branch Outlets—Threaded

45°Branch Outlets—Socket Welding

Rich production technology, advanced equipment, high automation degree and high production precision, complete molding. As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC, the company has won a number of national and provincial reputations.