Description

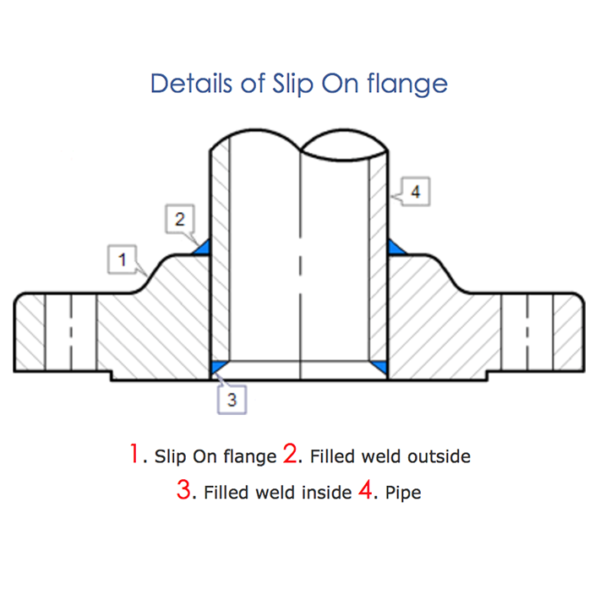

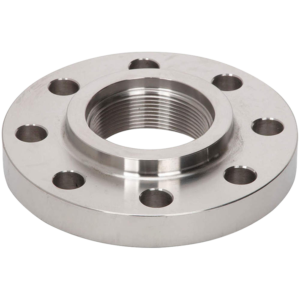

A slip-on flange is a type of flange used in piping systems to connect pipes or fittings. It is a circular disk-shaped fitting with a borehole in the center, which slips over the end of a pipe or fitting and is then welded in place.

Slip-on flanges are popular because they are relatively inexpensive and easy to install. They are commonly used in low-pressure, non-critical applications, such as water supply systems, sewage systems, and irrigation systems.

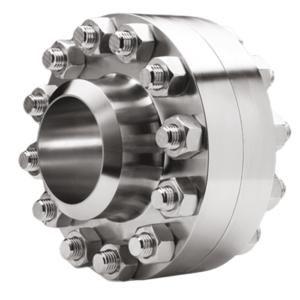

Slip-on flanges are available in a range of sizes and pressure ratings and can be made from a variety of materials such as carbon steel, stainless steel, and alloy steel. They are typically designed to be used with a raised face or flat face and are installed using a gasket to provide a leak-tight seal.

While slip-on flanges are simple and easy to use, they are not suitable for high-pressure or high-temperature applications, as they can be subject to leakage or failure under extreme conditions. In these situations, other types of flanges, such as weld neck or socket weld flanges, may be more appropriate.

A slip-on flange is positioned so the inserted end of the pipe or fitting is set short of the flange face by the thickness of the pipe wall plus 1/8 of an inch, which thus allows for a fillet weld inside the SO flange equal without doing any damage to the flange face. The back or outside of the slip-on flange or SO flange is also welded with a fillet weld.

Rich production technology, advanced equipment, high automation degree and high production precision, complete molding. As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC, the company has won a number of national, and provincial reputations.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 150lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

ASME/ANSI B16.5 150LB SLIP ON FLANGE/STANDARDS, DIMENSIONS & WEIGHT

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

| inch | dn | O | C | X | G | Y | B | BC | BH | BN | BD | ||

| 1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 22.40 | 60.50 | 15.80 | 4 | 1/2″ | 0.4 | 0.9 |

| 3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 27.70 | 69.90 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

| 1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 34.50 | 79.30 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

| 1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 43.20 | 88.90 | 15.80 | 4 | 1/2″ | 1.2 | 2.6 |

| 1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 49.50 | 98.60 | 15.80 | 4 | 1/2″ | 1.4 | 3.1 |

| 2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 62.00 | 120.70 | 19.10 | 4 | 5/8″ | 2.2 | 4.8 |

| 2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 74.70 | 139.70 | 19.10 | 4 | 5/8″ | 3.5 | 7.7 |

| 3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 90.70 | 152.40 | 19.10 | 4 | 5/8″ | 3.8 | 8.4 |

| 3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 103.40 | 177.80 | 19.10 | 8 | 5/8″ | 5 | 11 |

| 4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 116.10 | 190.50 | 19.10 | 8 | 5/8″ | 5.6 | 12.3 |

| 5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 143.80 | 215.90 | 22.40 | 8 | 3/4″ | 6.5 | 14.3 |

| 6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 170.70 | 241.30 | 22.40 | 8 | 3/4″ | 8.1 | 18 |

| 8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 221.50 | 298.50 | 22.40 | 8 | 3/4″ | 13 | 28.6 |

| 10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 276.40 | 362.00 | 25.40 | 12 | 7/8″ | 18.4 | 40 |

| 12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 327.20 | 431.80 | 25.40 | 12 | 7/8″ | 28.5 | 63 |

| 14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 359.20 | 476.30 | 28.50 | 12 | 1″ | 37.5 | 83 |

| 16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 410.50 | 539.80 | 28.50 | 16 | 1″ | 44.5 | 98 |

| 18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 461.80 | 577.90 | 31.80 | 16 | 1 1/8″ | 54 | 119 |

| 20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 513.10 | 635.00 | 31.80 | 20 | 1 1/8″ | 72 | 158 |

| 24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 616.00 | 749.30 | 35.10 | 20 | 1 1/4″ | 95 | 209 |

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 300lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

ASME/ANSI B16.5 300LB SLIP ON FLANGE/STANDARDS, DIMENSIONS & WEIGHT

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | G | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 22.4 | 66.5 | 15.7 | 4 | 1/2″ | 0.7 | 1.5 |

| 3/4″ | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 27.7 | 82.6 | 19.1 | 4 | 5/8″ | 1.2 | 2.6 |

| 1″ | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 34.5 | 88.9 | 19.1 | 4 | 5/8″ | 1.4 | 3.1 |

| 1-1/4″ | 32 | 133. 5 | 19.1 | 63.5 | 63.5 | 26.9 | 43.2 | 98.6 | 19.1 | 4 | 5/8″ | 1.8 | 4 |

| 1-1/2″ | 40 | 155. 5 | 20.6 | 69.9 | 73.2 | 30.2 | 49.5 | 114.3 | 22.4 | 4 | 5/8″ | 2.7 | 6 |

| 2″ | 50 | 165. 0 | 22.4 | 84.1 | 91.9 | 33.3 | 62 | 127 | 19.1 | 8 | 5/8″ | 3.2 | 7 |

| 2-1/2″ | 65 | 190. 5 | 25.4 | 100.1 | 104.6 | 38.1 | 74.7 | 149.4 | 22.4 | 8 | 3/4″ | 4.5 | 9.9 |

| 3″ | 80 | 209. 5 | 28.4 | 117.3 | 127 | 42.9 | 90.7 | 168.1 | 22.4 | 8 | 3/4″ | 5.9 | 13 |

| 3-1/2″ | 90 | 228. 5 | 30.2 | 133.4 | 139.7 | 44.5 | 103. 4 | 184.2 | 22.4 | 8 | 3/4″ | 7.5 | 16.5 |

| 4″ | 100 | 254. 0 | 31.8 | 146.1 | 157.2 | 47.8 | 116. 1 | 200.2 | 22.4 | 8 | 3/4″ | 10 | 22 |

| 5″ | 125 | 279. 5 | 35.1 | 177.8 | 185.7 | 50.8 | 143. 8 | 235 | 22.4 | 8 | 3/4″ | 12.5 | 27.5 |

| 6″ | 150 | 317. 5 | 36.6 | 206.2 | 215.9 | 52.3 | 170. 7 | 269.7 | 22.4 | 12 | 3/4″ | 16.5 | 36.4 |

| 8″ | 200 | 381. 0 | 41.1 | 260.4 | 269.7 | 62 | 221. 5 | 330.2 | 25.4 | 12 | 7/8″ | 25.5 | 56 |

| 10″ | 250 | 444. 5 | 47.8 | 320.5 | 323.9 | 66.5 | 276. 4 | 387.4 | 28.4 | 16 | 1″ | 35 | 77 |

| 12″ | 300 | 520. 5 | 50.8 | 374.7 | 381 | 73.2 | 327. 2 | 450.9 | 31.8 | 16 | 1 1/8″ | 52 | 115 |

| 14″ | 350 | 584. 0 | 53.8 | 425.5 | 412.8 | 76.2 | 359. 2 | 514..4 | 31.8 | 20 | 1 1/8″ | 73 | 161 |

| 16″ | 400 | 647. 5 | 57.2 | 482.6 | 469.9 | 82.6 | 410. 5 | 571.5 | 35.1 | 20 | 1 1/4″ | 88 | 194 |

| 18″ | 450 | 711. 0 | 60.5 | 533.4 | 533.4 | 88.9 | 461. 8 | 628.7 | 35.1 | 24 | 1 1/4″ | 115 | 253 |

| 20″ | 500 | 774. 5 | 63.5 | 587.2 | 584.2 | 95.3 | 513. 1 | 685.8 | 35.1 | 24 | 1 1/4″ | 139 | 306 |

| 24″ | 600 | 914. 5 | 69.9 | 701.5 | 692.2 | 106. 4 | 616. 0 | 812.8 | 41.1 | 24 | 1 1/2″ | 212 | 467 |

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 600lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

ASME/ANSI B16.5 600LB SLIP ON FLANGE/STANDARDS, DIMENSIONS & WEIGHT

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | G | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 22.9 | 66.5 | 15.7 | 4 | 1/2″ | 0.8 | 1.8 |

| 3/4″ | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 28.2 | 82.6 | 19.1 | 4 | 5/8″ | 1.4 | 3.1 |

| 1″ | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 35.1 | 88.9 | 19.1 | 4 | 5/8″ | 1.7 | 3.7 |

| 1-1/4″ | 32 | 133. 5 | 20.6 | 63.5 | 63.5 | 28.4 | 43.7 | 98.6 | 19.1 | 4 | 5/8″ | 2.1 | 4.6 |

| 1-1/2″ | 40 | 155. 5 | 22.4 | 69.9 | 73.2 | 31.8 | 50 | 114.3 | 22.4 | 4 | 3/4″ | 3.1 | 6.8 |

| 2″ | 50 | 165. 0 | 25.4 | 84.1 | 91.9 | 36.6 | 62.5 | 127 | 19.1 | 8 | 5/8″ | 3.9 | 8.6 |

| 2-1/2″ | 65 | 190. 5 | 28.4 | 100.1 | 104.6 | 41.1 | 75.4 | 149.4 | 22.4 | 8 | 3/4″ | 5.4 | 11.9 |

| 3″ | 80 | 209. 5 | 31.8 | 117.3 | 127 | 46 | 91.4 | 168.1 | 22.4 | 8 | 3/4″ | 7.3 | 16.1 |

| 3-1/2″ | 90 | 228. 5 | 35.1 | 133.4 | 139.7 | 49.3 | 104.1 | 184.2 | 25.4 | 8 | 7/8″ | 9 | 19.8 |

| 4″ | 100 | 273. 0 | 38.1 | 152.4 | 157.2 | 53.8 | 116.8 | 215.9 | 25.4 | 8 | 7/8″ | 16.5 | 36..4 |

| 5″ | 125 | 330. 0 | 44.5 | 189 | 185.7 | 60.5 | 144.5 | 266.7 | 28.4 | 8 | 1″ | 28.5 | 62.8 |

| 6″ | 150 | 355. 5 | 47.8 | 222.3 | 215.9 | 66.5 | 171.5 | 292.1 | 28.4 | 12 | 1″ | 36.2 | 79.8 |

| 8″ | 200 | 419. 0 | 55.6 | 273.1 | 269.7 | 76.2 | 222.3 | 349.3 | 31.8 | 12 | 1 1/8″ | 51.5 | 114 |

| 10″ | 250 | 508. 0 | 63.5 | 342.9 | 323.9 | 85.9 | 277.4 | 431.8 | 35.1 | 16 | 1 1/4″ | 76.2 | 168 |

| 12″ | 300 | 559. 0 | 66.5 | 400.1 | 381 | 91.9 | 328.2 | 489 | 35.1 | 20 | 1 1/4″ | 89.5 | 197 |

| 14″ | 350 | 603. 5 | 69.9 | 431.8 | 412.8 | 93.7 | 360.2 | 527.1 | 38.1 | 20 | 1 3/8″ | 102 | 225 |

| 16″ | 400 | 686. 0 | 76.2 | 495.3 | 469.9 | 106. 4 | 411.2 | 603.3 | 41.1 | 20 | 1 1/2″ | 150 | 330 |

| 18″ | 450 | 743. 0 | 82.6 | 546.1 | 533.4 | 117. 3 | 462.3 | 654.1 | 44.5 | 20 | 1 5/8″ | 180 | 397 |

| 20″ | 500 | 813. 0 | 88.9 | 609.6 | 584.2 | 127. 0 | 514.4 | 723.9 | 44.5 | 24 | 1 5/8″ | 231 | 509 |

| 24″ | 600 | 940. 0 | 101.6 | 717.6 | 692.2 | 139. 7 | 616 | 838.2 | 50.8 | 24 | 1 7/8″ | 330 | 727 |

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 900lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

ASME/ANSI B16.5 900LB SLIP ON FLANGE/STANDARDS, DIMENSIONS & WEIGHT

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Length Hub | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 120.7 | 22.4 | 38.1 | 31.8 | 22.4 | 82.6 | 22.4 | 4 | 3/4″ | 1.8 | 4 |

| 3/4″ | 20 | 130 | 25.4 | 44.5 | 35.1 | 27.7 | 88.9 | 22.4 | 4 | 3/4″ | 2.4 | 5.3 |

| 1″ | 25 | 149.4 | 28.4 | 52.3 | 41.1 | 34.5 | 101.6 | 25.4 | 4 | 7/8″ | 3.6 | 7.9 |

| 1-1/4″ | 32 | 158.8 | 28.4 | 63.5 | 41.1 | 43.2 | 111.3 | 25.4 | 4 | 7/8″ | 4.1 | 9 |

| 1-1/2″ | 40 | 177.8 | 31.8 | 69.9 | 44.5 | 49.5 | 124 | 28.4 | 4 | 1″ | 5.4 | 12 |

| 2″ | 50 | 215.9 | 38.1 | 104.6 | 57.2 | 62 | 165.1 | 25.4 | 8 | 7/8″ | 10.5 | 23.1 |

| 2-1/2″ | 65 | 244.3 | 41.1 | 124 | 63.5 | 74.7 | 190.5 | 28.4 | 8 | 1″ | 15.8 | 34.8 |

| 3″ | 80 | 241.3 | 38.1 | 127 | 53.8 | 90.7 | 190.5 | 25.4 | 8 | 7/8″ | 12.3 | 27 |

| 4″ | 100 | 292.1 | 44.5 | 158.8 | 69.9 | 116.1 | 235 | 31.8 | 8 | 1 1/8″ | 23.2 | 51 |

| 5″ | 125 | 349.3 | 50.8 | 190.5 | 79.2 | 143.8 | 279.4 | 35.1 | 8 | 1 1/4″ | 37.5 | 82.6 |

| 6″ | 150 | 381 | 55.6 | 235 | 85.9 | 170.7 | 317.5 | 31.8 | 12 | 1 1/8″ | 48.3 | 106 |

| 8″ | 200 | 469.9 | 63.5 | 298.5 | 101.6 | 221.5 | 393.7 | 38.1 | 12 | 1 3/8″ | 75 | 165 |

| 10″ | 250 | 546.1 | 69.9 | 368.3 | 108 | 276.4 | 469.9 | 38.1 | 16 | 1 3/8″ | 110 | 243 |

| 12″ | 300 | 609.6 | 79.2 | 419.1 | 117.3 | 327.2 | 533.4 | 38.1 | 20 | 1 3/8″ | 146 | 322 |

| 14″ | 350 | 641.4 | 85.9 | 450.9 | 130 | 359.2 | 558.8 | 41.1 | 20 | 1 1/2″ | 172 | 379 |

| 16″ | 400 | 704.9 | 88.9 | 508 | 133.4 | 410.5 | 616 | 44.5 | 20 | 1 5/8″ | 192 | 423 |

| 18″ | 450 | 787.4 | 101.6 | 565.2 | 152.4 | 461.8 | 685.8 | 50.8 | 20 | 1 7/8″ | 272 | 600 |

| 20″ | 500 | 857.3 | 108 | 622.3 | 158.8 | 513.1 | 749.3 | 53.8 | 20 | 2″ | 330 | 727 |

| 24″ | 600 | 1041 | 139.7 | 749.3 | 203.2 | 616 | 901.7 | 66.5 | 20 | 2 1/2″ | 632 | 1393 |

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 1500lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

ASME/ANSI B16.5 1500LB SLIP ON FLANGE/STANDARDS, DIMENSIONS & WEIGHT

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Length Hub | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | Approx. Weight | ||

| inch | dn | O | C | X | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2″ | 15 | 120.7 | 22.4 | 38.1 | 31.8 | 22.4 | 82.6 | 22.4 | 4 | 3/4″ | 1.8 | 4 |

| 3/4″ | 20 | 130 | 25.4 | 44.5 | 35.1 | 27.7 | 88.9 | 22.4 | 4 | 3/4″ | 2.4 | 5.3 |

| 1″ | 25 | 149.4 | 28.4 | 52.3 | 41.1 | 34.5 | 101.6 | 25.4 | 4 | 7/8″ | 3.6 | 7.9 |

| 1-1/4″ | 32 | 158.8 | 28.4 | 63.5 | 41.1 | 43.2 | 111.3 | 25.4 | 4 | 7/8″ | 4.1 | 9 |

| 1-1/2″ | 40 | 177.8 | 31.8 | 69.9 | 44.5 | 49.5 | 124 | 28.4 | 4 | 1″ | 5.4 | 12 |

| 2″ | 50 | 215.9 | 38.1 | 104.6 | 57.2 | 62 | 165.1 | 25.4 | 8 | 7/8″ | 10.5 | 23.1 |

| 2-1/2″ | 65 | 244.3 | 41.1 | 124 | 63.5 | 74.7 | 190.5 | 28.4 | 8 | 1″ | 15.8 | 34.8 |

| 3″ | 80 | 266.7 | 47.8 | 133.4 | 190.5 | 25.4 | 8 | 7/8″ | 21.5 | 43 | ||

| 4″ | 100 | 311.2 | 53.8 | 162.1 | 235 | 31.8 | 8 | 1 1/8″ | 31 | 68.3 | ||

| 5″ | 125 | 374.7 | 73.2 | 196.9 | 279.4 | 35.1 | 8 | 1 1/4″ | 58.8 | 130 | ||

| 6″ | 150 | 393.7 | 82.6 | 228.6 | 317.5 | 31.8 | 12 | 1 1/8″ | 74 | 163 | ||

| 8″ | 200 | 482.6 | 91.9 | 292.1 | 393.7 | 38.1 | 12 | 1 3/8″ | 112 | 247 | ||

| 10″ | 250 | 584.2 | 108 | 368.3 | 469.9 | 38.1 | 16 | 1 3/8″ | 184 | 406 | ||

| 12″ | 300 | 673.1 | 124 | 450.9 | 533.4 | 38.1 | 20 | 1 3/8″ | 264 | 581 | ||

| 14″ | 350 | 749.3 | 133.4 | 495.3 | 558.8 | 41.1 | 20 | 1 1/2″ | ||||

| 16″ | 400 | 825.5 | 146.1 | 552.5 | 616 | 44.5 | 20 | 1 5/8″ | ||||

| 18″ | 450 | 914.4 | 162.1 | 596.9 | 685.8 | 50.8 | 20 | 1 7/8″ | ||||

| 20″ | 500 | 984.3 | 177.8 | 641.4 | 749.3 | 53.8 | 20 | 2″ | ||||

| 24″ | 600 | 1168.4 | 203.2 | 762 | 901.7 | 66.5 | 20 | 2 1/2″ | ||||

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

Elite offers a wide range of flanges like PL, SW, BL, WN, SO, LJ, ASME/ANSI B16.5 2500lb Slip on Flange etc., which is precisely engineered in accordance with international quality standards totally. These flanges are highly durable, corrosion resistant and reliable. Our range of flanges finds application in industries like engineering, construction, chemical, oil field and power plant. We offer these flanges in various dimensions as per the specifications provided by our clients. To gain optimum client satisfaction, we ensure safe packaging and prompt delivery of the ordered consignment.

DESCRIPTION OF SLIP ON FLANGE

| Pipe Normal Diam. | Outside Diameter of Flange | Diameter Bore | thickness of Flange | Diameter of Raised Face | Height of Raised Face | Diameter of Hub at Base | Length through Hub | No. of Holes | Diameter of Holes | Diameter of Bolts | Diameter of Bolt Circle | Weight |

| inch | O | C | G | X | Y | BN | BH | BD | BC | lbs. | ||

| 1/2 | 5.25 | 0.88 | 1.19 | 1.38 | 0.25 | 1.69 | 1.56 | 4 | 0.88 | 3/4 | 3.5 | 7 |

| 3/4 | 5.5 | 1.09 | 1.25 | 1.69 | 0.25 | 2 | 1.69 | 4 | 0.88 | 3/4 | 3.75 | 9 |

| 1 | 6.25 | 1.36 | 1.38 | 2 | 0.25 | 2.25 | 1.88 | 4 | 1 | 7/8 | 4.25 | 12 |

| 1 1/4 | 7.25 | 1.70 | 1.5 | 2.5 | 0.25 | 2.88 | 2.06 | 4 | 1.12 | 1 | 5.12 | 18 |

| 1 1/2 | 8 | 1.95 | 1.75 | 2.88 | 0.25 | 3.12 | 2.38 | 4 | 1.25 | 1 1/8 | 5.75 | 25 |

| 2 | 9.25 | 2.44 | 2 | 3.62 | 0.25 | 3.75 | 2.75 | 8 | 1.12 | 1 | 6.75 | 38 |

| 2 1/2 | 10.5 | 2.94 | 2.25 | 4.12 | 0.25 | 4.5 | 3.13 | 8 | 1.25 | 1 1/8 | 7.75 | 55 |

| 3 | 12 | 3.57 | 2.62 | 5 | 0.25 | 5.25 | 3.63 | 8 | 1.38 | 1 1/4 | 9 | 83 |

| 4 | 14 | 4.57 | 3 | 6.19 | 0.25 | 6.5 | 4.25 | 8 | 1.62 | 1 1/2 | 10.75 | 127 |

| 5 | 16.5 | 5.66 | 3.62 | 7.31 | 0.25 | 8 | 5.13 | 8 | 1.88 | 1 3/4 | 12.75 | 210 |

| 6 | 19 | 6.72 | 4.25 | 8.5 | 0.25 | 9.25 | 6 | 8 | 2.12 | 2 | 14.5 | 323 |

| 8 | 21.75 | 8.72 | 5 | 10.62 | 0.25 | 12 | 7 | 12 | 2.12 | 2 | 17.25 | 485 |

| 10 | 26.5 | 10.88 | 6.5 | 12.75 | 0.25 | 14.75 | 9 | 12 | 2.62 | 2 1/2 | 21.25 | 925 |

| 12 | 30 | 12.88 | 7.25 | 15 | 0.25 | 17.38 | 10 | 12 | 2.88 | 2 3/4 | 24.38 | 1300 |

Note:

Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.