Description

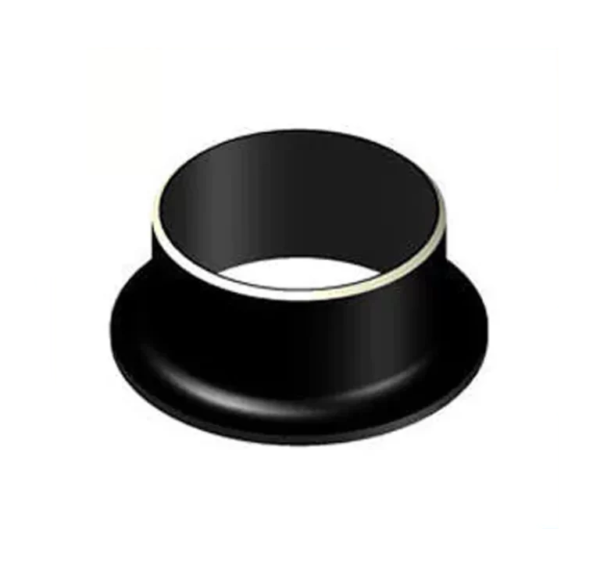

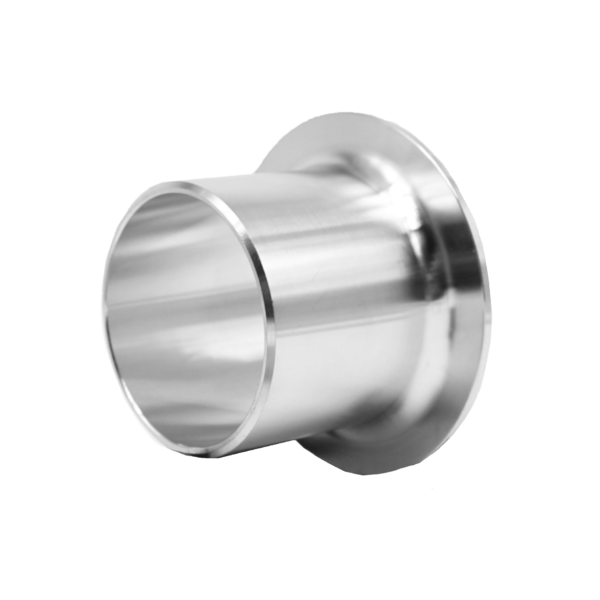

Stub ends are fittings used in piping systems to connect pipes of different materials, sizes or flange ratings. They are used in combination with lap joint flanges to create a joint that can be easily assembled and disassembled for maintenance or repair purposes.

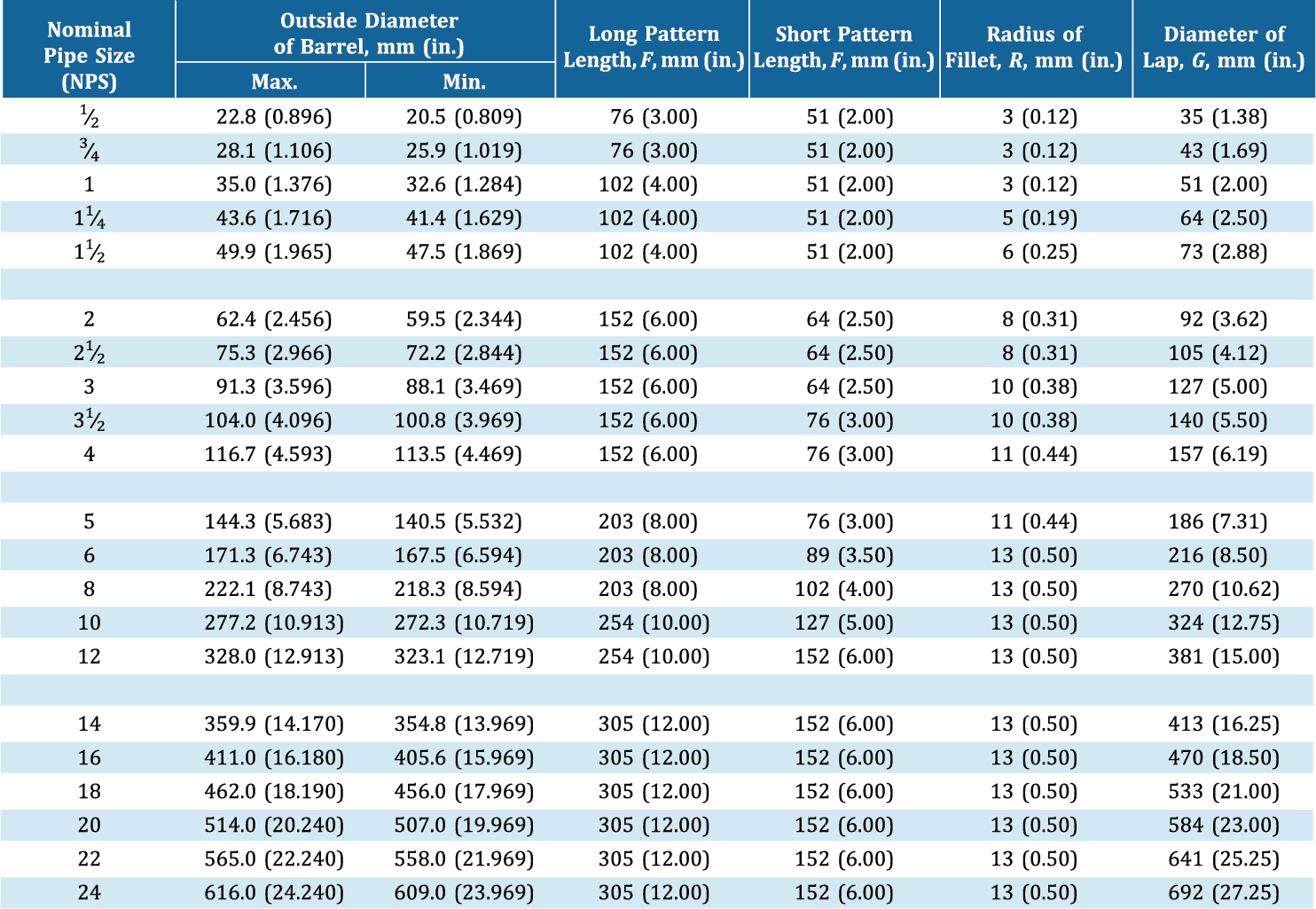

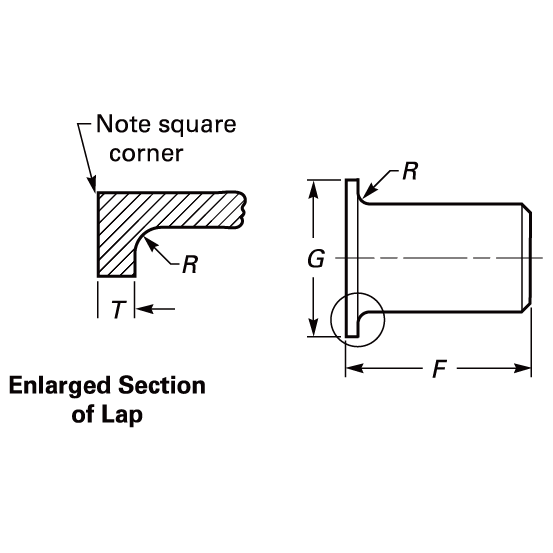

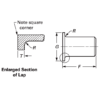

A stub end is a short piece of pipe with a weld bevel on one end and a plain end on the other end. The weld bevel allows the stub end to be welded to the pipe, while the plain end acts as a flange face. The lap joint flange is then bolted to the stub end, creating a loose flange connection.

Stub ends are available in various materials such as carbon steel, stainless steel, and alloy steel. They can be manufactured in different lengths, wall thicknesses, and diameters to fit various piping applications.

Stub ends are commonly used in applications where frequent dismantling is required, such as in pipelines carrying corrosive fluids, high-temperature applications, and applications where thermal expansion is an issue. They are also commonly used in petrochemical, chemical, and power generation industries.

Rich production technology, advanced equipment, high automation degree and high production precision, complete molding. As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC, the company has won a number of national and provincial reputations.