Description

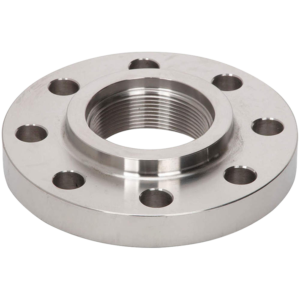

An orifice flange is a type of flange used in piping systems to facilitate the installation of an orifice plate or flow meter in a pipe. It consists of a standard flange with a concentric or eccentric circular hole machined in the center. The orifice plate is placed in the hole and held in place by bolts, creating a restriction in the flow of fluid through the pipe.

Orifice flanges are commonly used in the oil and gas industry, as well as in chemical processing, power generation, and other applications where precise flow measurement and control are required. They are available in a range of sizes and pressure ratings and can be made from a variety of materials such as carbon steel, stainless steel, and alloy steel.

The orifice plate in an orifice flange can be designed with different shapes and sizes of holes, depending on the specific application. The size and shape of the hole are chosen to create a specific level of flow restriction, which is used to measure the flow rate of fluid through the pipe.

Orifice flanges can also be used in conjunction with other types of flow control devices, such as control valves or flow meters, to accurately measure and control the flow of fluid through the pipe. They are generally more expensive than standard flanges, but their precision and accuracy make them essential for many critical applications.

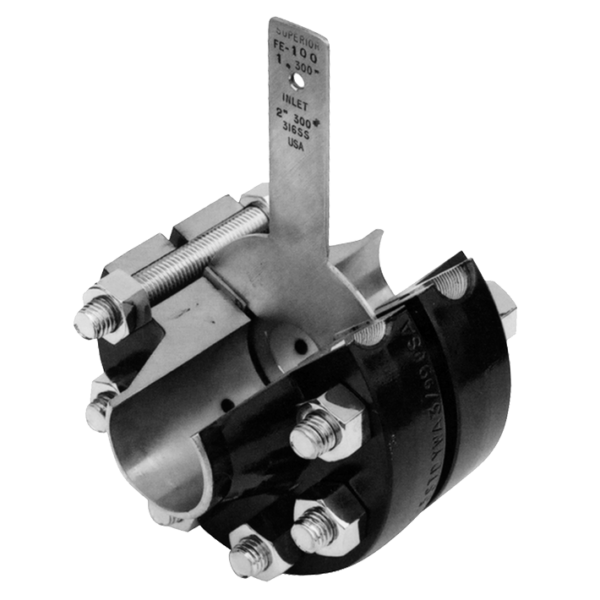

Orifice flanges are usually applying for metering the volumetric flow rate of liquids and gasses through a pipe. Two orifice flanges are called an orifice flange union. Each flange comes with two pipe taps for measuring the pressure drop of the flow through an orifice plate. Orifice plates do not come with the flanges and are sized based on the requirements of the process. Two jack screws are used to spread the flanges apart in order to change the orifice plate. This flange is normally available in weld neck, slip-on, and threaded flanges. Orifice flanges generally have a raised face.

Rich production technology, advanced equipment, high automation degree and high production precision, complete molding. As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC, the company has won a number of national, and provincial reputations.