Description

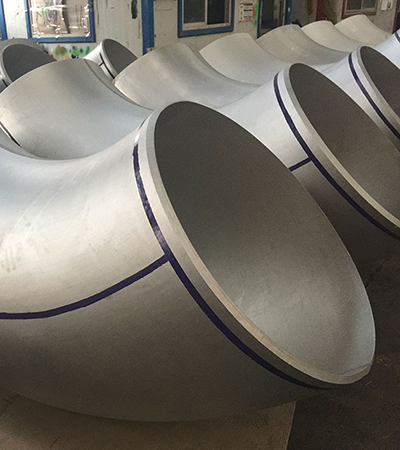

A butt-welded elbow is a type of piping-fitting elbow that is joined to a pipeline using a butt-welding process. This involves welding the elbow directly to the pipe, creating a strong and secure connection that is resistant to leaks and corrosion.

Butt welded elbows are commonly used in industrial applications where high pressure, high temperature, or corrosive fluids are being conveyed. They are available in different sizes, materials, and degrees of bend, such as 90 degrees, 45 degrees, and 22.5 degrees, to allow for greater flexibility and customization in piping system design.

The installation of butt welded elbows requires careful preparation of the pipe ends, including cleaning, beveling, and aligning the edges to ensure a proper fit. The edges are then welded together using a welding machine or torch, creating a strong and durable joint.

Butt-welded elbows are preferred over other types of elbow fittings in high-pressure and high-temperature applications, where the use of threaded or socket-welded elbows may result in weaker connections or leaks. However, they require more time and labor to install, as well as specialized equipment and training, making them more expensive than other types of fittings.

45 degree

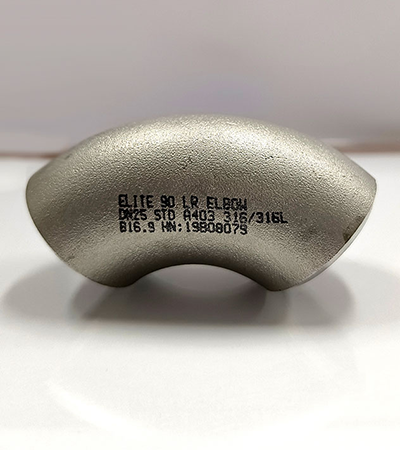

90 degree

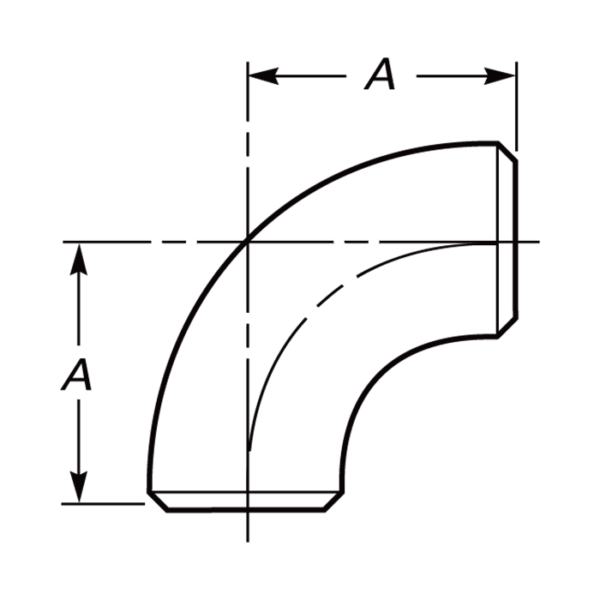

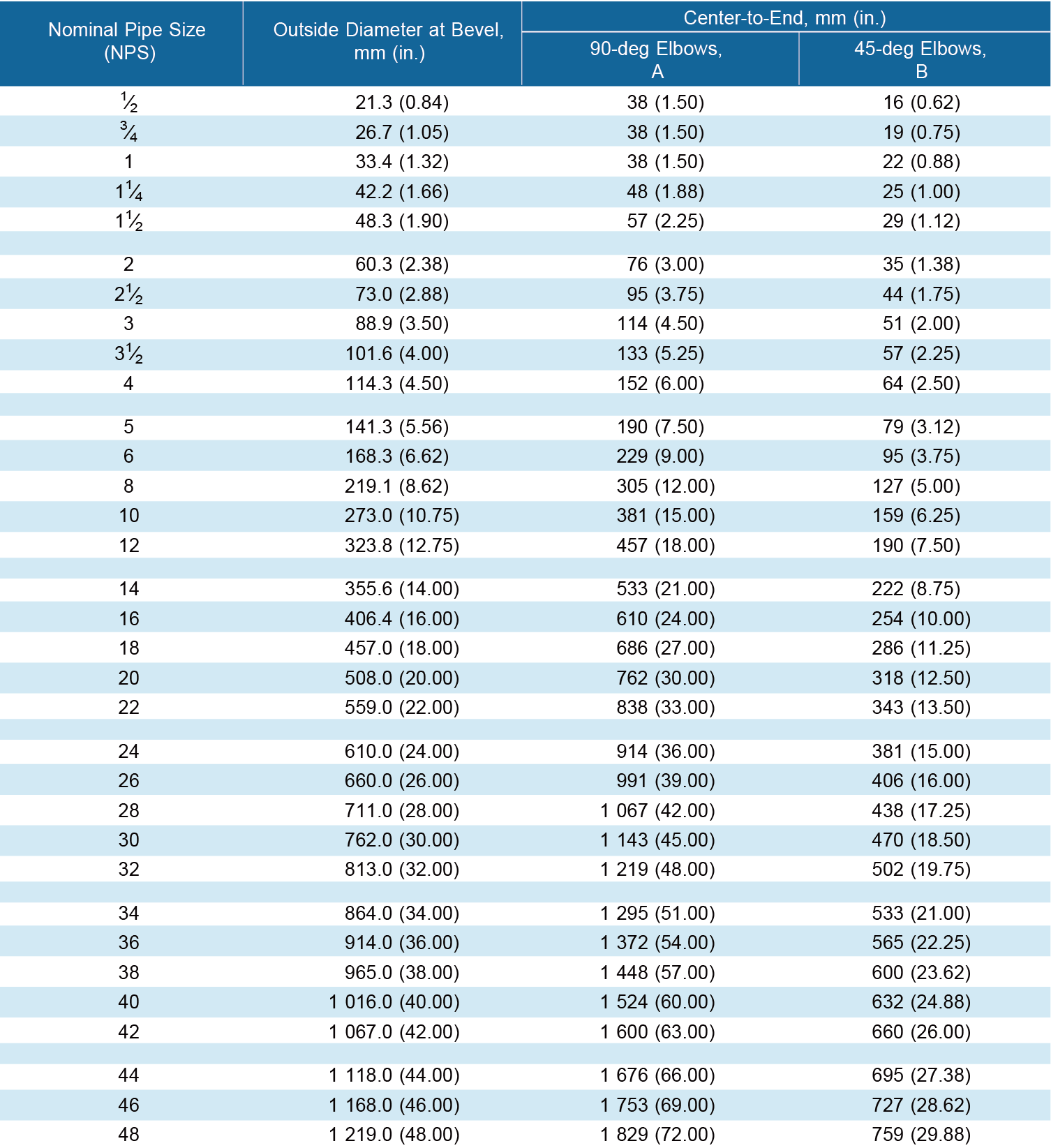

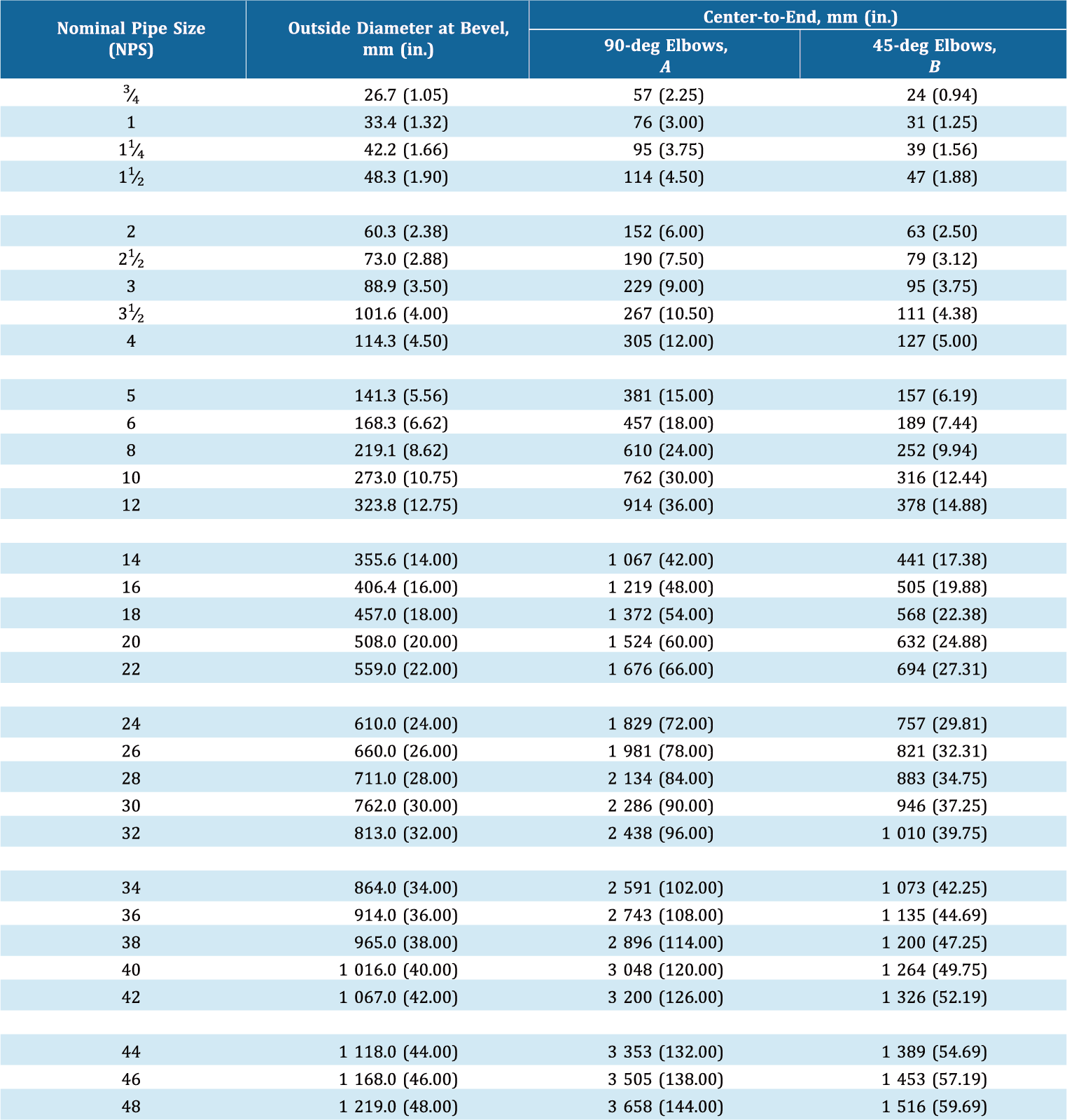

Dimensions of Long Radius Elbows

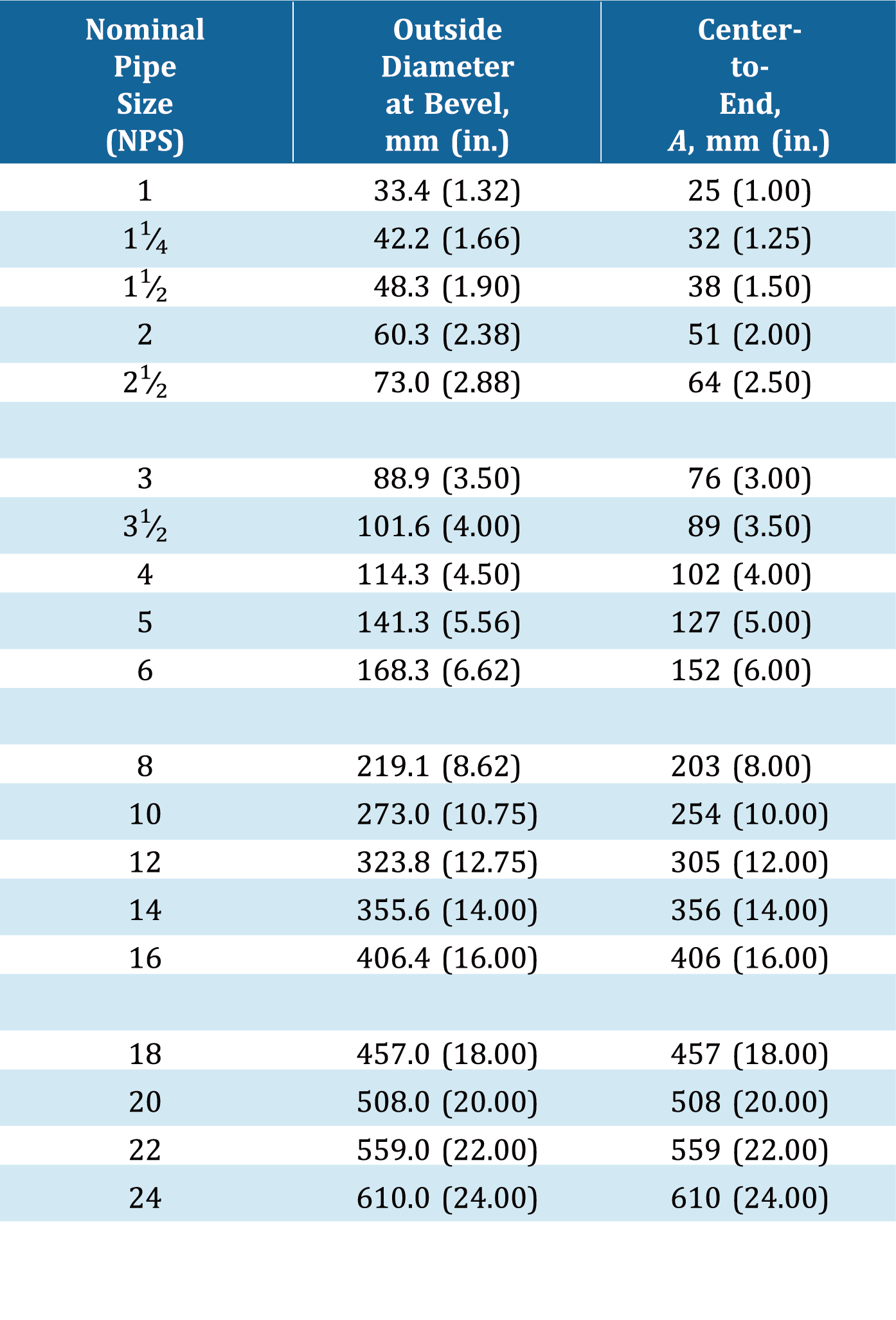

Dimensions of Short Radius Elbows

Dimensions of 3D Radius Elbows

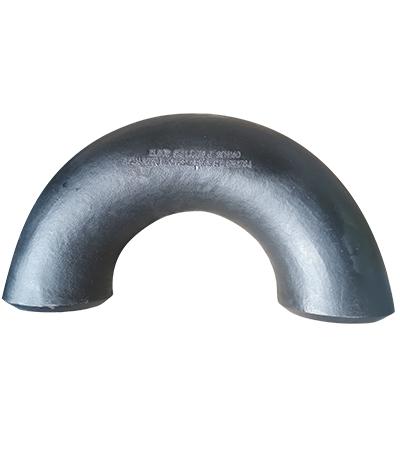

180 degree

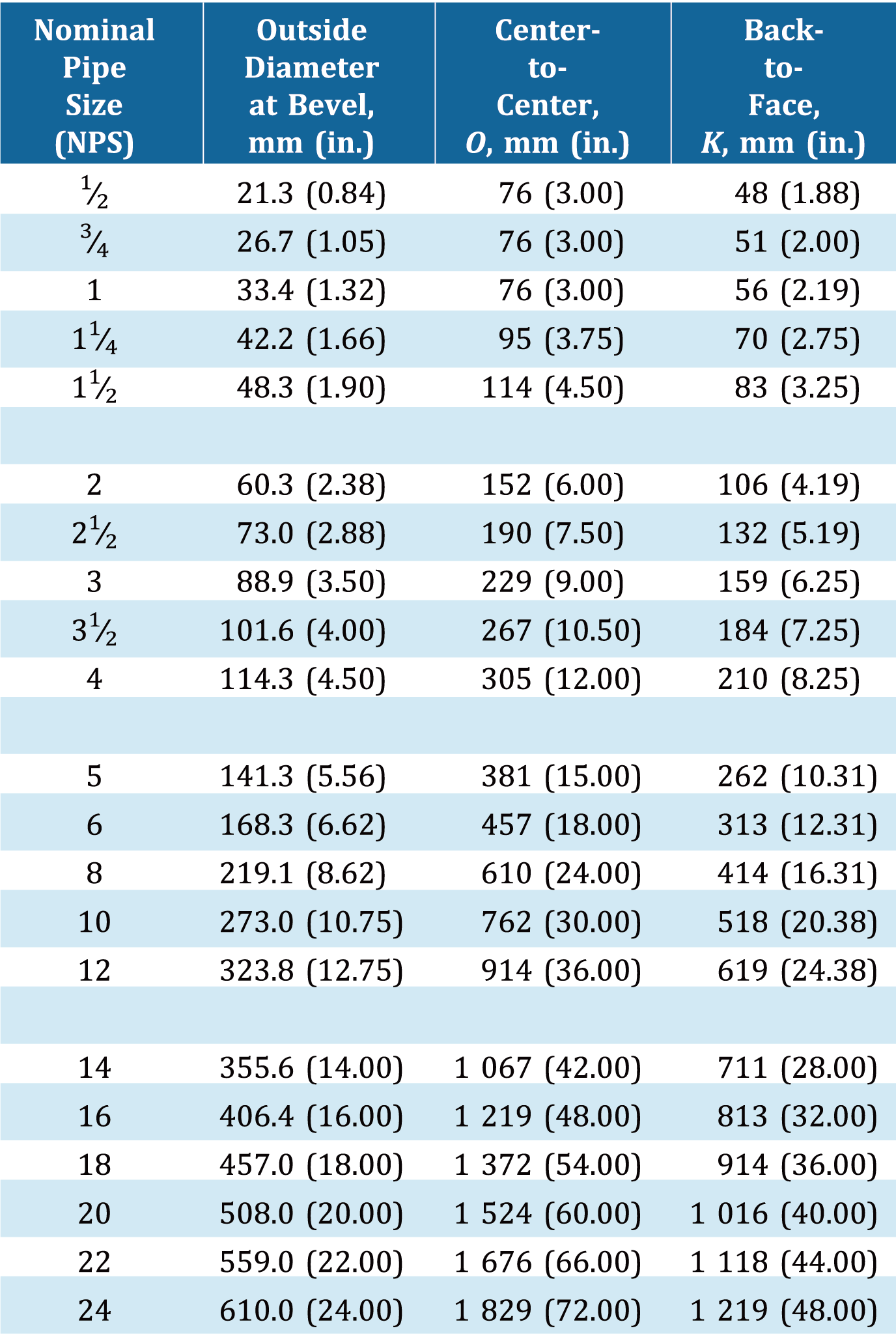

Dimensions of Long Radius Returns

Reducing elbow

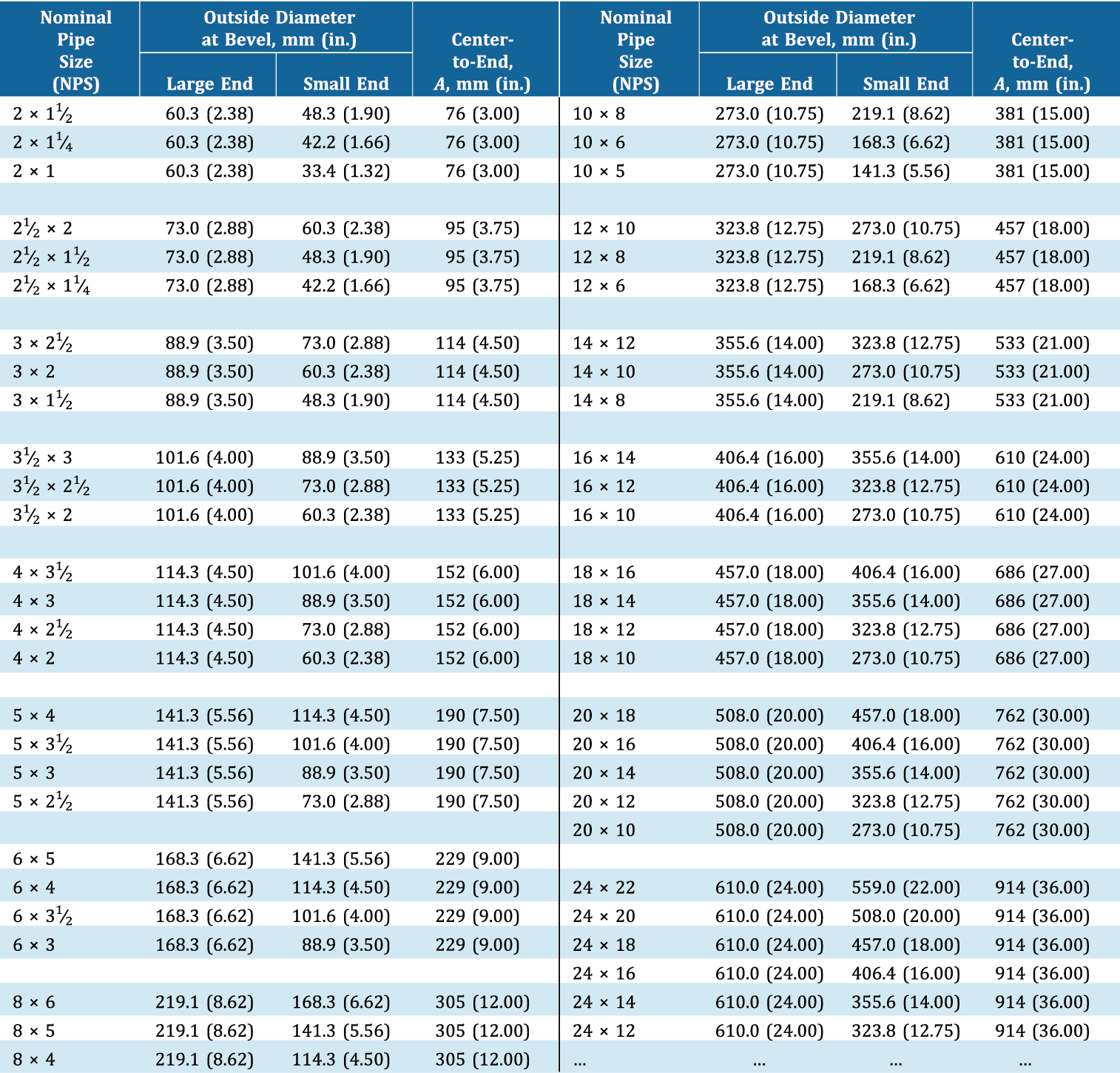

Dimensions of Long Radius Reducing Elbows

Large-diameter welding Elbow

Rich production technology, advanced equipment, high automation degree and high production precision, complete molding. As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC, the company has won a number of national and provincial reputations.