Description

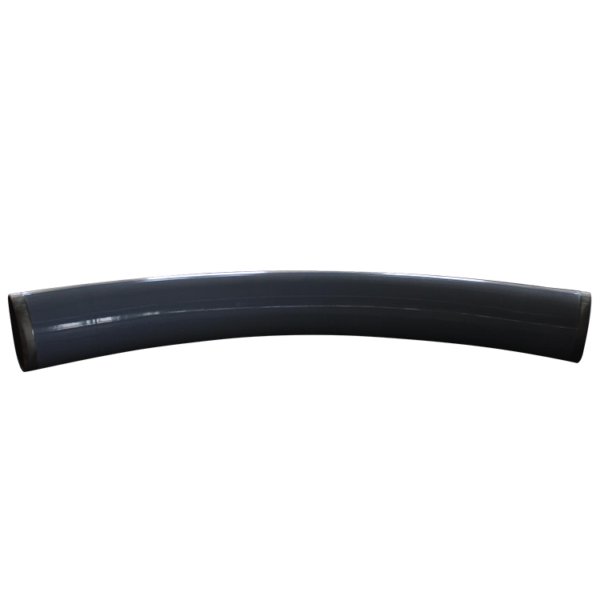

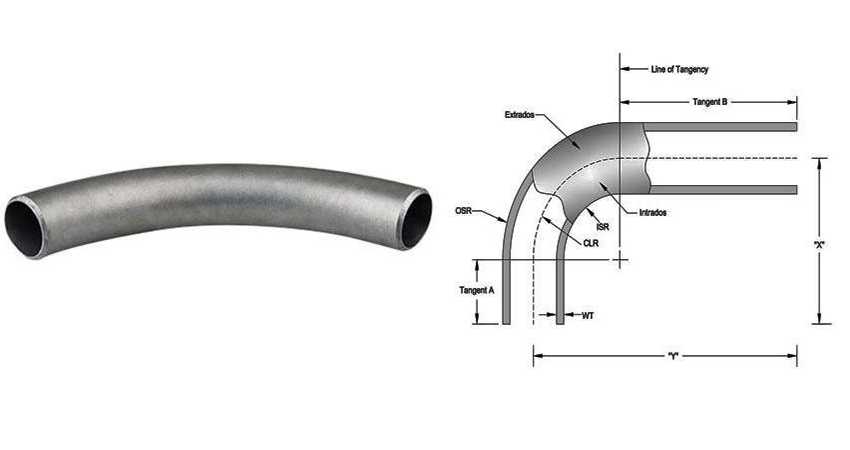

A fitting bend is a type of piping fitting that is used to change the direction of a piping system. It is commonly used in plumbing, HVAC, and industrial applications where a change in the direction of flow or the orientation of the pipe is required.

Fitting bends are available in different angles, such as 45 degrees, 90 degrees, and 180 degrees, to accommodate various piping configurations. They can be made from different materials, such as carbon steel and stainless steel, depending on the application.

Fitting bends are designed to provide a smooth and gradual change in the direction of the pipe, which helps to reduce turbulence and pressure drop in the system. They are also available in different styles, such as long radius bends, short radius bends, and standard bends, which allow for greater flexibility and customization in piping system design.

The installation of fitting bends requires careful consideration of the pipe size, material, pressure, temperature, and fluid being conveyed to ensure proper fit and performance. In some cases, a combination of fitting bends, tees, and other fittings may be required to achieve the desired piping configuration.

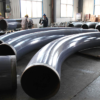

Induction Bend is widely used in petrochemical, coal chemical, refining, oil and gas transportation, marine environment, electric power, heating and other projects. Through hot simmer, cold simmer and other manufacturing processes to change the direction of the pipeline, to meet the needs of users.

Rich production technology, advanced equipment, high automation degree and high production precision, complete molding. As the designated supplier of major energy enterprise groups under the jurisdiction of SASAC, the company has won a number of national and provincial reputations.