Description

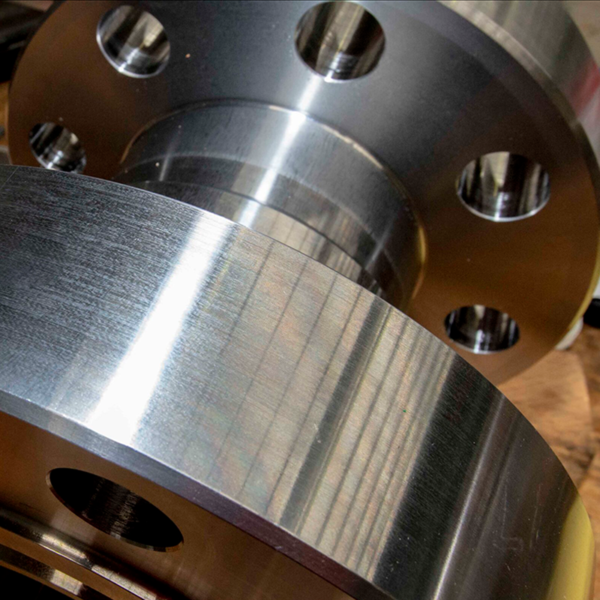

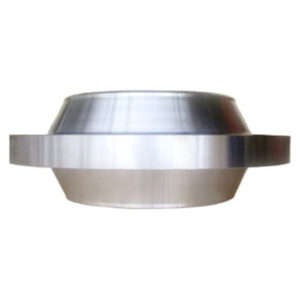

API 6A flanges are a type of flange designed and manufactured in accordance with the American Petroleum Institute (API) specification 6A. This specification outlines the requirements for wellhead and Christmas tree equipment used in the oil and gas industry.

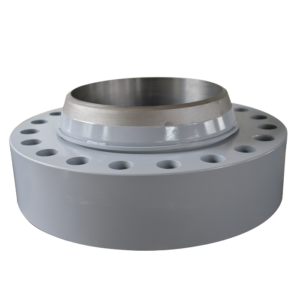

API 6A flanges are typically used in high-pressure and high-temperature applications and are available in a range of sizes, pressure ratings, and materials. The most common materials used for API 6A flanges are carbon steel, stainless steel, and alloy steel.

API 6A flanges are designed to withstand harsh operating conditions such as high pressure, extreme temperatures, and corrosive environments. They are also designed to provide a leak-tight seal between two pieces of equipment, such as a wellhead and a Christmas tree.

API 6A flanges are subject to rigorous testing and inspection to ensure their quality and performance. Some of the tests that are commonly performed on API 6A flanges include hydrostatic testing, gas testing, and magnetic particle inspection.

Overall, API 6A flanges are widely used in the oil and gas industry for various applications such as wellheads, Christmas trees, valves, and other equipment where high-pressure and high-temperature conditions are present.

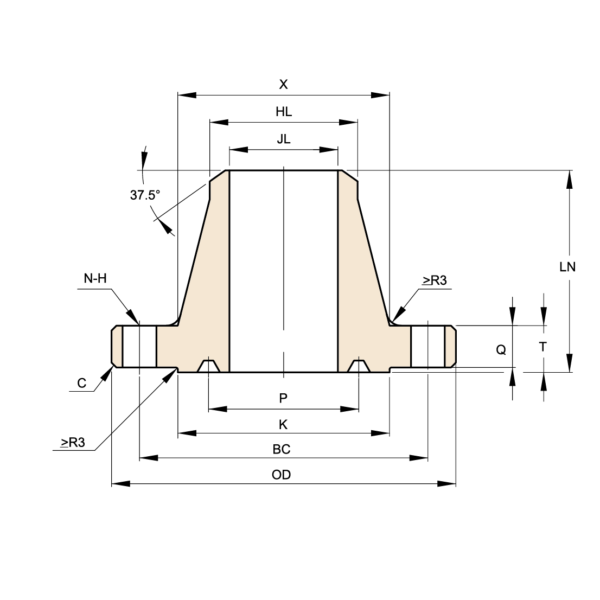

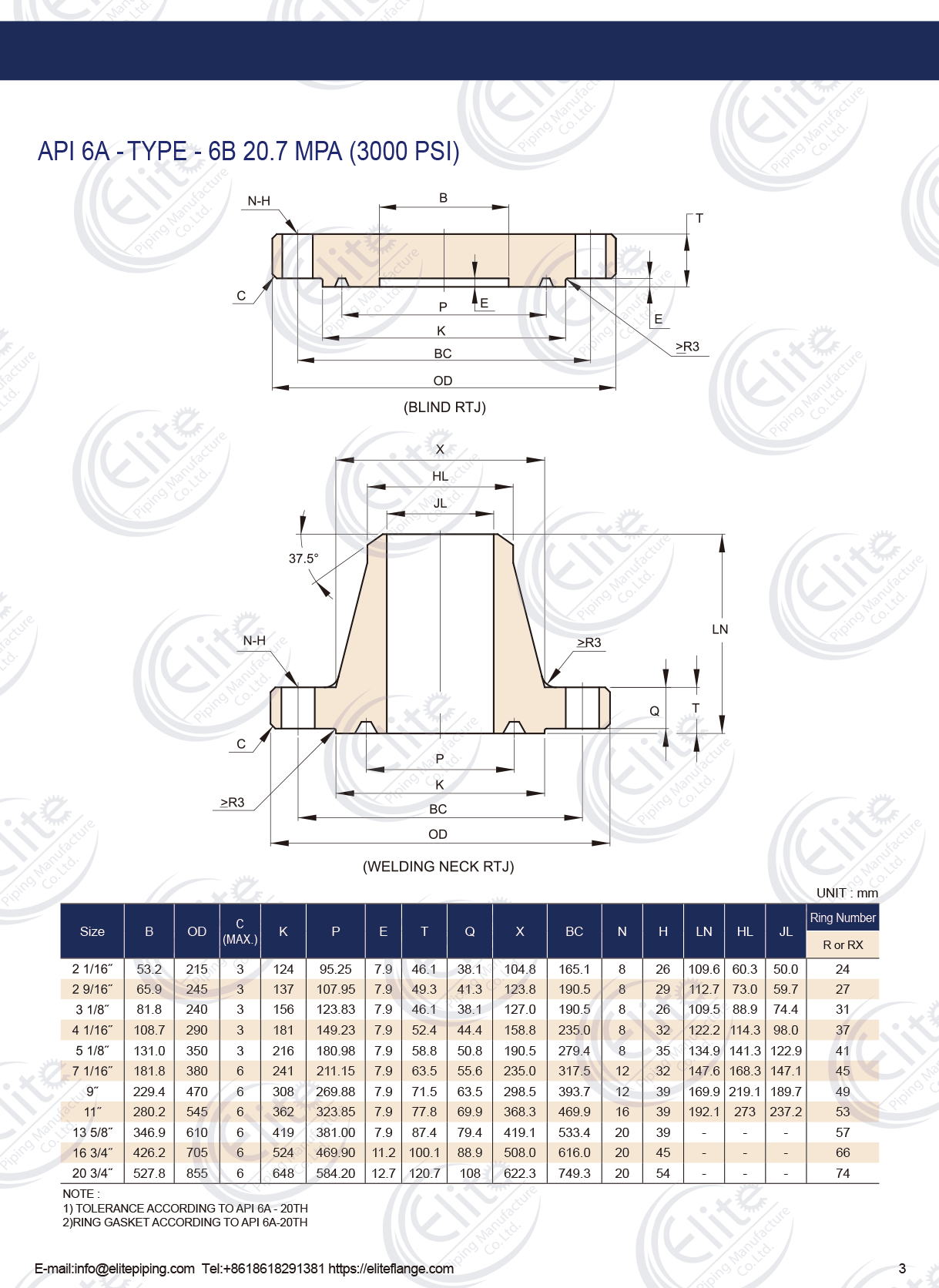

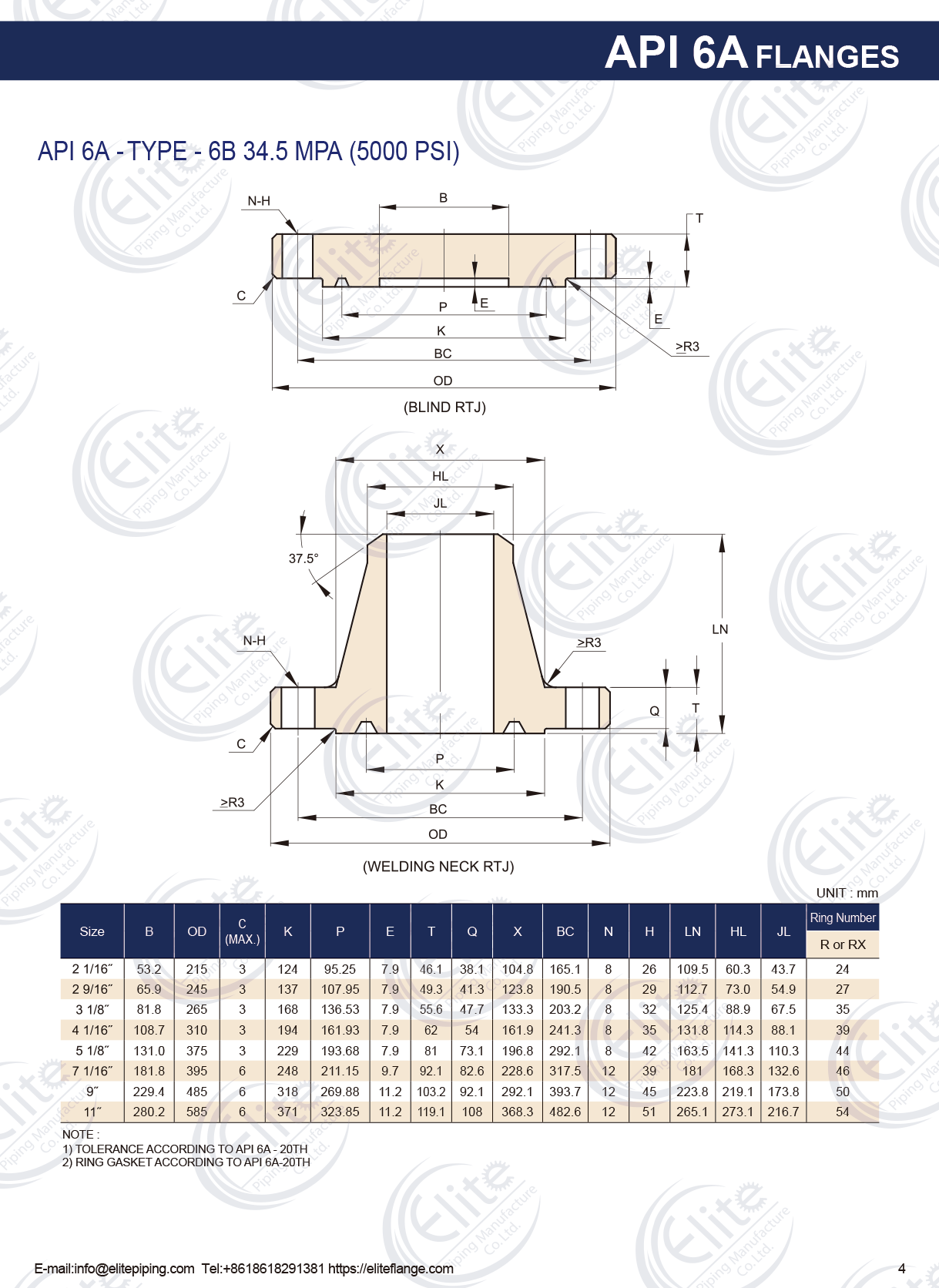

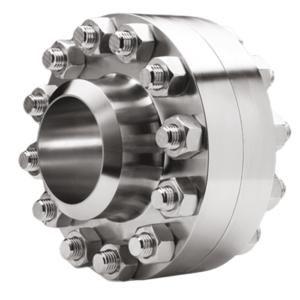

Type 6B Flanges:

Type 6B flanges are of the ring joint type and are not designed for face-to-face makeup. The connection make-up bolting force reacts on the metallic ring gasket. Type 6B flanges are of through bolted or studded design.

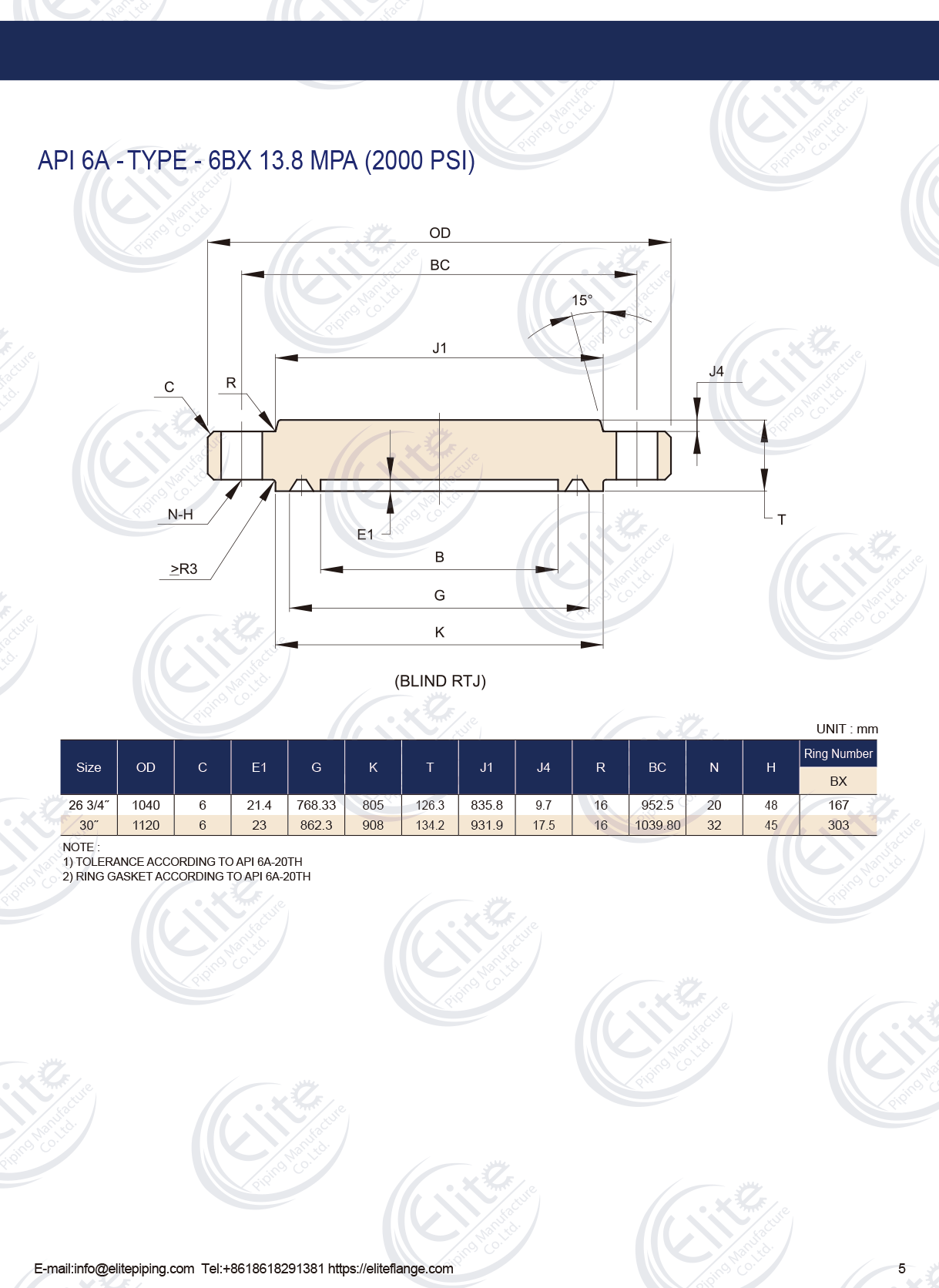

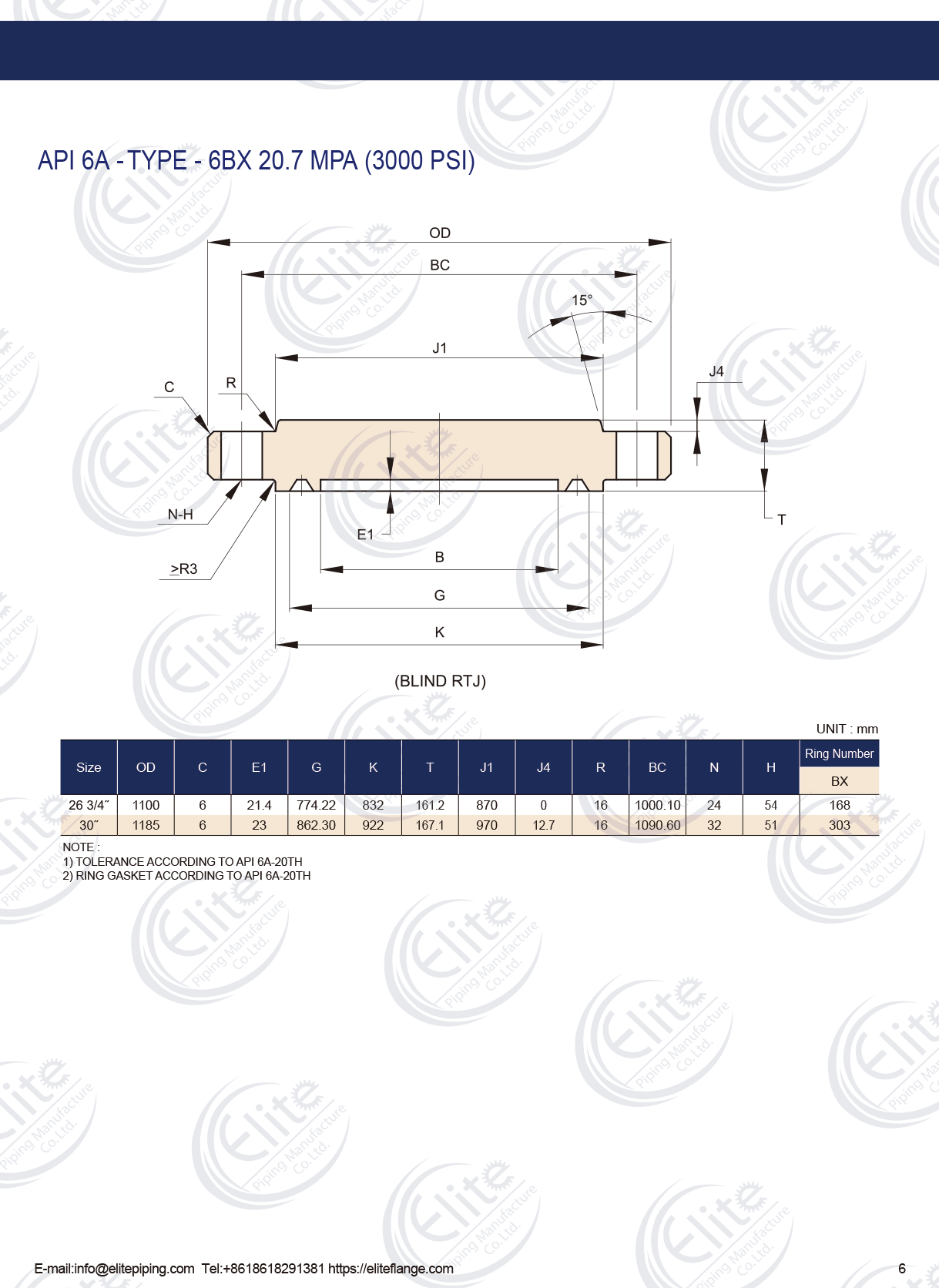

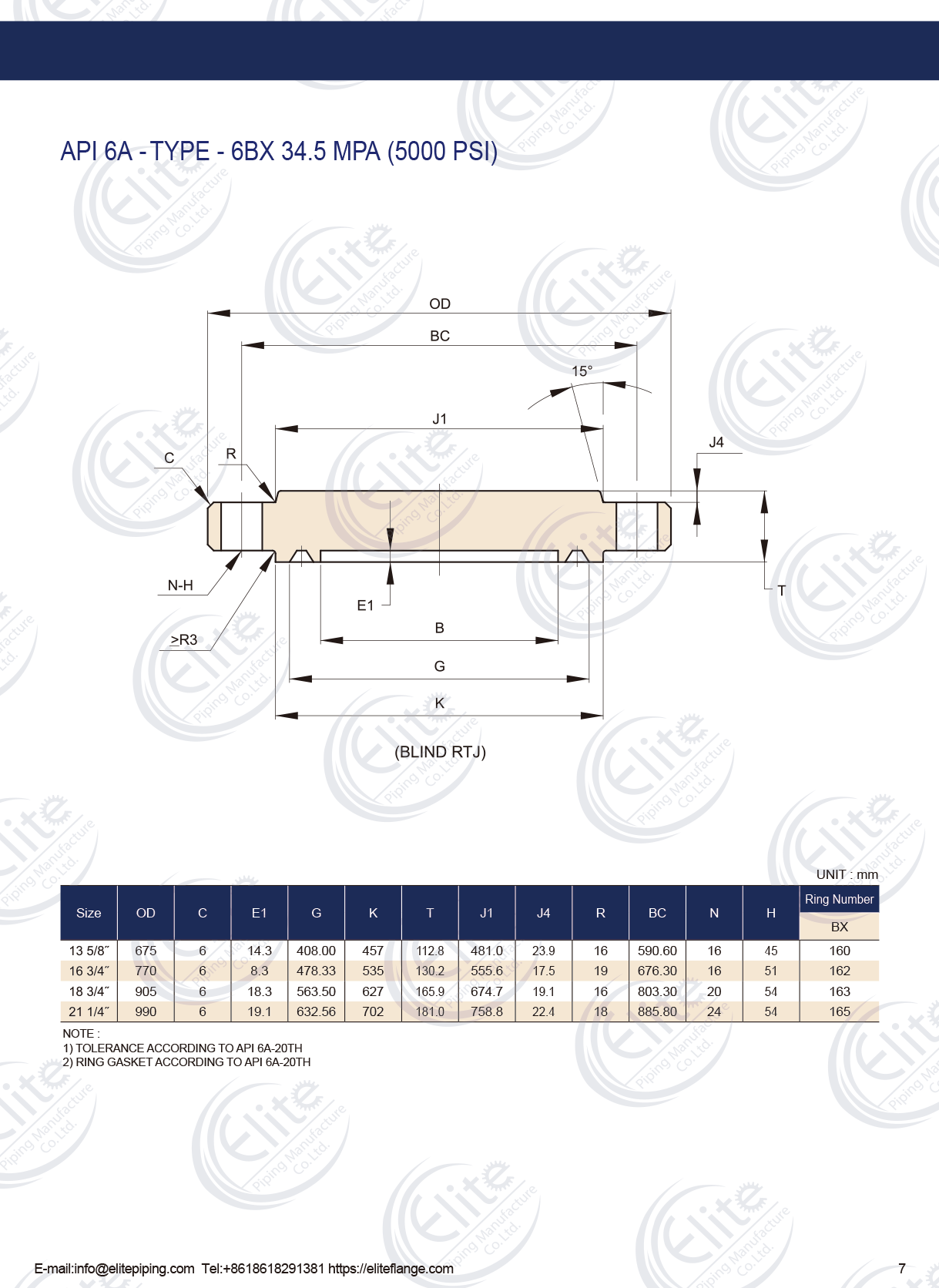

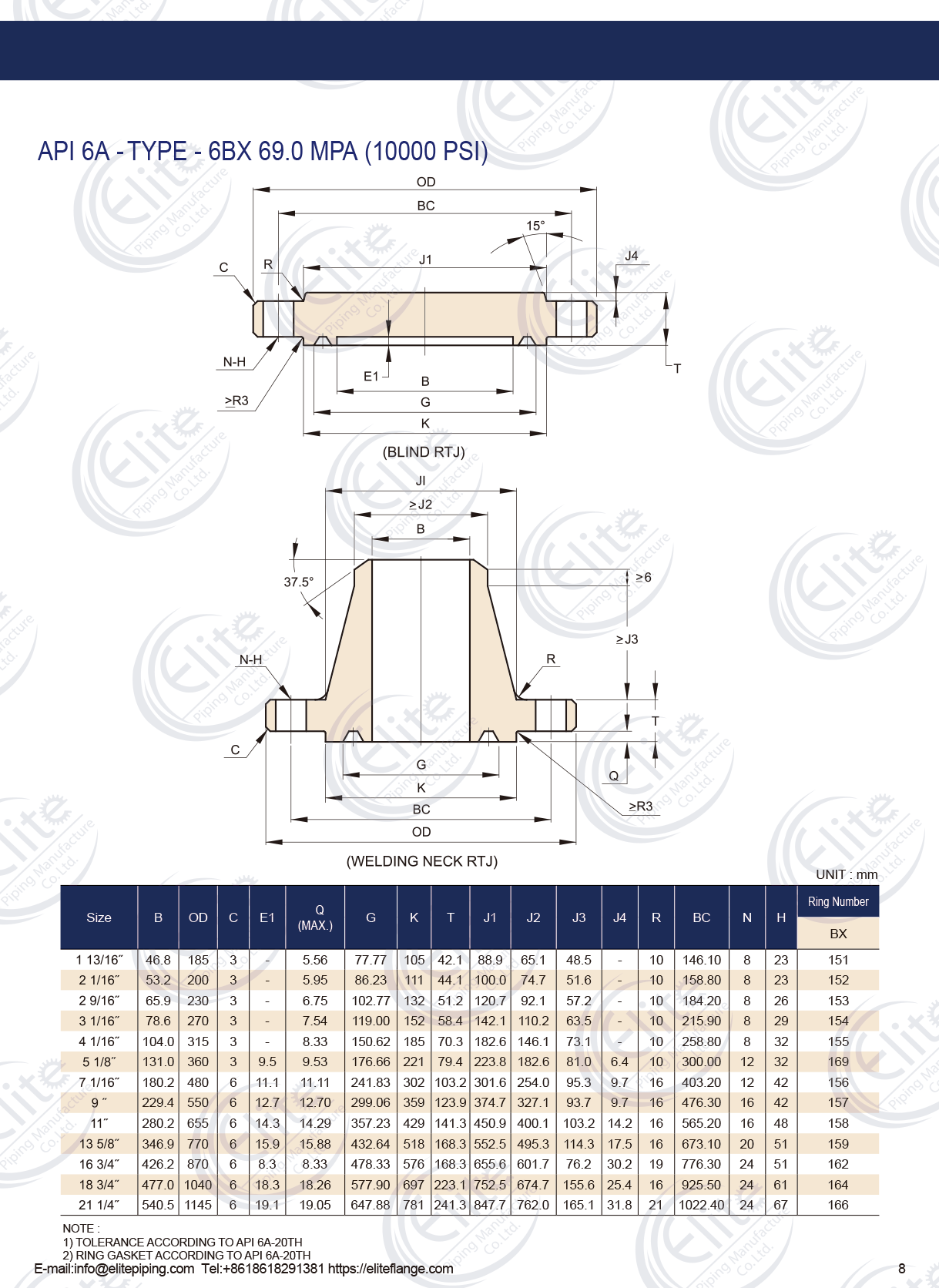

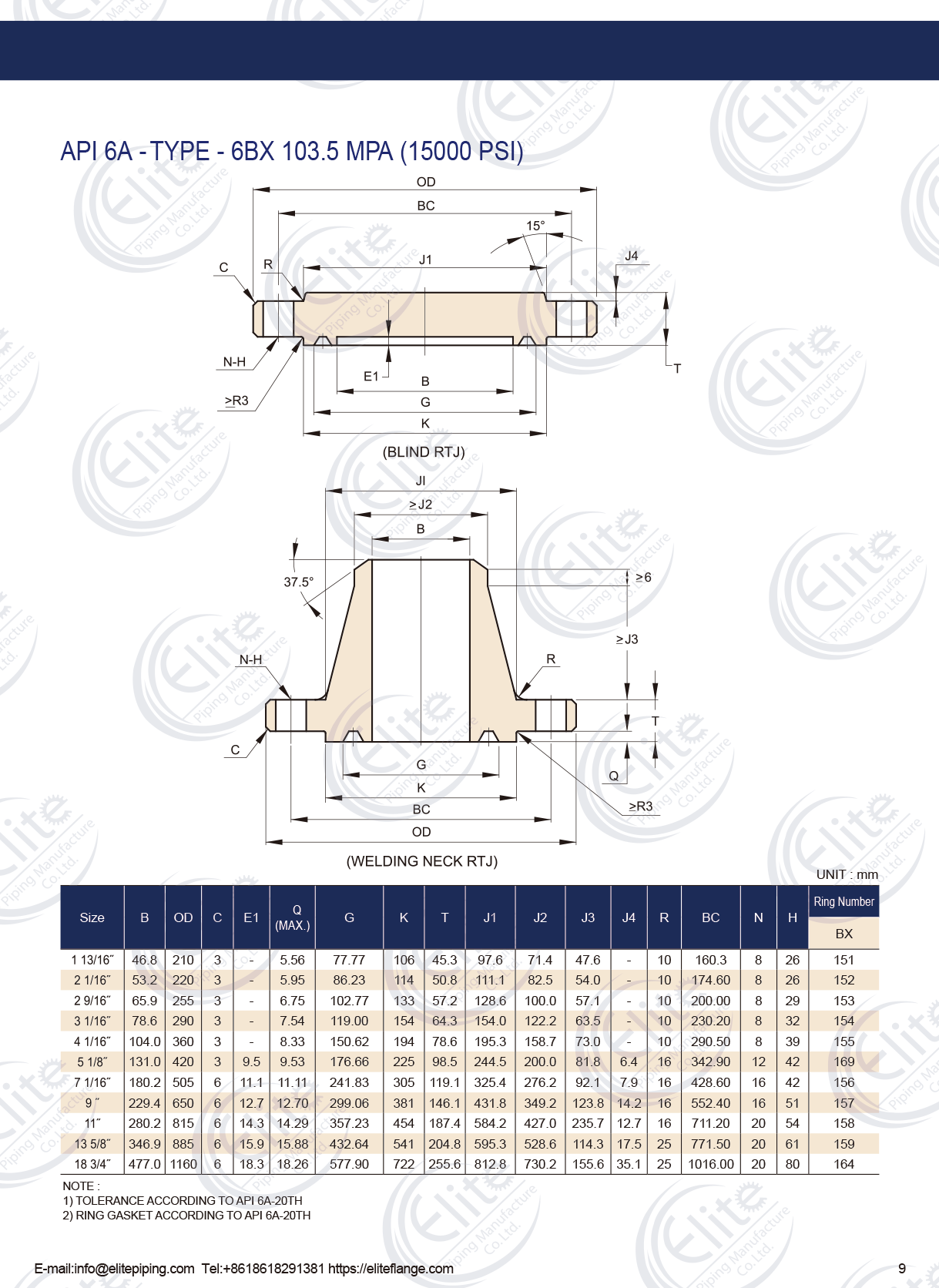

Type 6BX Flanges:

Type 6BX flanges are of the ring joint type and are designed with a raised face. Depending on the tolerances, the connection make-up bolting force may react on the raised face of the flange when the gasket has been properly seated.

This support prevents damage to the flange or gasket from excessive bolt torque. Therefore, one of the flanges in the 6 BX connection shall have a raised face. Type 6BX flanges are of through bolted or studded design. Face-to-face contact is not necessary for the proper functioning of the 6BX flange.

| Flange Size | Working Pressure (PSI) | Outside Diameter | Number of Bolt Holes | Diameter of Bolt Holes | Length of Bolts | API Ring Gasket |

|---|---|---|---|---|---|---|

| 1-13/16″ | 10,000 | 7-3/8″ | 8 | 3/4″ | 5-1/4″ | BX-151 |

| 1-13/16″ | 15,000 | 8-3/16″ | 8 | 7/8″ | 6″ | BX-151 |

| 1-13/16″ | 20,000 | 10-1/8″ | 8 | 1″ | 7-3/4″ | BX-151 |

| 2-1/16″ | 2,000 | 6-1/2″ | 8 | 5/8″ | 5/8″ | R-23 |

| 2-1/16″ | 3,000/5,000 | 8-1/2″ | 8 | 7/8″ | 7/8″ | R-24 |

| 2-1/16″ | 10,000 | 7-7/8″ | 8 | 3/4″ | 3/4″ | BX-152 |

| 2-1/16″ | 15,000 | 8-3/4″ | 8 | 7/8″ | 7/8″ | BX-152 |

| 2-1/16″ | 20,000 | 11-5/16″ | 8 | 1-1/8″ | 1-1/8″ | BX-152 |

| 2-9/16″ | 2,000 | 7-1/2″ | 8 | 3/4″ | 5-1/4″ | R-26 |

| 2-9/16″ | 3,000/5,000 | 9-5/8″ | 8 | 1″ | 7″ | R-27 |

| 2-9/16″ | 10,000 | 9-1/8″ | 8 | 7/8″ | 6-1/4″ | BX-153 |

| 2-9/16″ | 15,000 | 10″ | 8 | 1″ | 7″ | BX-153 |

| 2-9/16″ | 20,000 | 12-13/16″ | 8 | 1-1/4″ | 9-1/2″ | BX-153 |

| 3-1/8″ | 2,000 | 8-1/4″ | 8 | 3/4″ | 5-1/2″ | R-31 |

| 3-1/8″ | 3,000 | 9-1/2″ | 8 | 7/8″ | 6-1/4″ | R-31 |

| 3-1/8″ | 5,000 | 10-1/2″ | 8 | 1-1/8″ | 7-3/4″ | R-35 |

| 3-1/16″ | 10,000 | 10-5/8″ | 8 | 1″ | 7-1/4″ | BX-154 |

| 3-1/16″ | 15,000 | 11-5/16″ | 8 | 1-1/8″ | 8″ | BX-154 |

| 3-1/16″ | 20,000 | 14-1/16″ | 8 | 1-3/8″ | 10-3/4″ | BX-154 |

| 4-1/16″ | 2,000 | 10-3/4″ | 8 | 7/8″ | 6-1/4″ | R-37 |

| 4-1/16″ | 3,000 | 11-1/2″ | 8 | 1-1/8″ | 7-1/2″ | R-37 |

| 4-1/16″ | 5,000 | 12-1/4″ | 8 | 1-1/8″ | 8-3/8″ | BX-155 |

| 4-1/16″ | 20,000 | 17-9/16″ | 8 | 1-3/4″ | 12-3/4″ | BX-155 |

| 5-1/8″ | 5,000 | 14-3/4″ | 8 | 1-1/2″ | 10-3/4″ | R-44 |

| 7-1/16″ | 2,000 | 14″ | 12 | 1″ | 7-1/2″ | R-45 |

| 7-1/16″ | 3,000 | 15″ | 12 | 1-1/8″ | 8-1/2″ | R-45 |

| 7-1/16″ | 5,000 | 15-1/2″ | 12 | 1-3/8″ | 11-1/4″ | R-46 |

| 7-1/16″ | 10,000 | 18-7/8″ | 12 | 1-1/2″ | 11-3/4″ | BX-156 |

| 7-1/16″ | 15,000 | 19-7/8″ | 16 | 1-1/2″ | 13″ | BX-156 |

| 7-1/16″ | 20,000 | 24-13/16″ | 16 | 2″ | 17-3/4″ | BX-156 |

| 9″ | 2,000 | 16-1/2″ | 12 | 1-1/8″ | 8-1/2″ | R-49 |

| 9″ | 3,000 | 18-1/2″ | 12 | 1-3/8″ | 9-1/2″ | R-49 |

| 9″ | 5,000″ | 19″ | 12 | 1-5/8″ | 12-1/2″ | R-50 |

| 9″ | 10,000 | 21-3/4″ | 16 | 1-1/2″ | 13-1/4″ | BX-157 |

| 9″ | 15,000 | 25-1/2″ | 16 | 1-7/8″ | 16″ | BX-157 |

| 11″ | 2,000 | 20″ | 16 | 1-1/4″ | 9-1/4″ | R-53 |

| 11″ | 3,000 | 21-1/2″ | 16 | 1-3/8″ | 10″ | R-53 |

| 11″ | 5,000 | 23″ | 12 | 1-7/8″ | 14-1/4″ | R-54 |

| 11″ | 10,000 | 25-3/4″ | 16 | 1-3/4″ | 15-3/8″ | BX-158 |

| 11″ | 15,000 | 32″ | 20 | 2″ | 19-1/2″ | BX-158 |

| 13-5/8″ | 2,000 | 22″ | 20 | 1-1/4″ | 9-1/2″ | R-57 |

| 13-5/8″ | 3,000 | 24″ | 20 | 1-3/8″ | 10-3/4″ | R-57 |

| 13-5/8″ | 5,000 | 26-1/2″ | 16 | 1-5/8″ | 12-3/4″ | BX-160 |

| 13-5/8″ | 10,000 | 30-1/4″ | 20 | 1-7/8″ | 17-3/4″ | BX-159 |

| 13-5/8″ | 15,000 | 34-7/8″ | 20 | 2-1/4″ | 21″ | BX-159 |

| 16-3/4″ | 2,000 | 27″ | 20 | 1-1/2″ | 10-3/4″ | R-65 |

| 16-3/4″ | 3,000 | 27-3/4″ | 20 | 1-5/8″ | 12-1/4″ | R-66 |

| 16-3/4″ | 5,000 | 30-3/8″ | 16 | 1-78″ | 14-3/4″ | BX-162 |

| 16-3/4″ | 10,000 | 34-5/16″ | 24 | 1-7/8″ | 17-3/4″ | BX-162 |

| 18-3/4″ | 5,000 | 35-5/8″ | 20 | 2″ | 18″ | BX-163 |

| 16-3/4″ | 10,000 | 40-15/16″ | 24 | 2-1/4″ | 23″ | BX-164 |

| 20-3/4″ | 3,000 | 33-3/4″ | 20 | 2″ | 15-1/4″ | R-74 |

| 21-1/4″ | 2,000 | 32″ | 24 | 1-5/8″ | 12-1/2″ | R-73 |

| 21-1/4″ | 5,000 | 39″ | 24 | 2″ | 19″ | BX-165 |

| 21-1/4″ | 10,000 | 45″ | 24 | 2-1/2″ | 24-3/4″ | BX-166 |

| 26-3/4″ | 2,000 | 41″ | 20 | 1-3/4″ | 14-1/4″ | BX-167 |

| 21-1/4″ | 3,000 | 43-3/8″ | 24 | 2″ | 17-1/2″ | BX-168 |